Ten great case studies have made the Information Management Best Practice shortlist at the Digital Construction Awards 2026.

This category recognises the benefits of best practice in information management, whether in the construction of a new built asset, in the management of an existing built asset or within an organisation.

This was an especially popular and competitive category. Here are the 10 entries that made the shortlist.

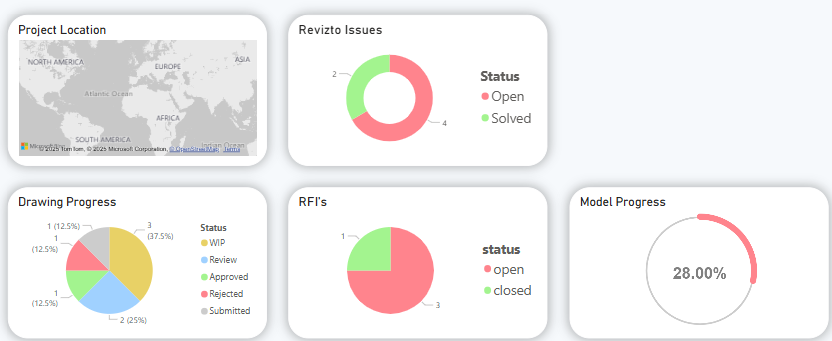

10 Dock information management transformation – CDE managed service | Babcock International/Assystem

The 10 Dock Redevelopment Programme forms part of Babcock’s multi-year investment in modernising Devonport Royal Dockyard, one of the UK’s most critical naval infrastructure assets supporting submarine deep maintenance and refit. With more than 30 design and construction work packages, more than 250 core stakeholders and 15 organisations involved, the programme required exceptional coordination of technical information across a complex and highly regulated environment.

Given the number of contributing partners and digital systems in use, information exchange processes had naturally become intricate. Maintaining a consistent, authoritative view of design data required significant coordination effort, and review cycles could occasionally extend beyond planned durations, creating the potential for schedule pressure.

To further strengthen visibility and streamline document governance, Babcock commissioned Assystem to help develop a structured CDE managed service (CMS).

The CMS provided a structured, 19650-aligned framework combining embedded expertise, digital integration and real-time analytics.

A joint team was established, comprising a CDE information manager, CDE champions and project support officers (PSOs) working alongside Babcock’s contract managers. Embedding digital specialists directly within delivery teams ensured hands-on control of transmittals, metadata, and approvals.

A total of 17 core service functions standardised planning, verification and transmittal processes. The BIM dashboard reporting system was re-engineered with Power BI, enabling managers to monitor overdue items, review durations and change review management (CRM) close-out rates in real-time. Furthermore, a single live tracker linked Task Information Delivery Plans, the Master Information Delivery Plan and CRM cycles, creating a continuous digital thread from task to programme level.

Two early workstreams streamlined existing data management: approximately 2,000 historical pre-construction deliverables were consolidated from local P:drives into the governed CDE; and legacy BDRS items were reviewed and closed through staged approval cycles.

Structured training with the BIM core team embedded a shared understanding of workflows and dashboards. PSOs acted as ‘digital liaisons’, promoting consistent practice across engineering and document-control teams.

Since mobilisation in 2024, measurable gains have been realised:

- 69% faster review cycles (from 13 days to four), improving efficiency;

- 21% reduction in overdue deliverables (circa 260 items cleared);

- 33% increase in metadata and workflow compliance;

- 100% traceability of all transmittals; and

- resubmission incidents reduced from 22 to five per quarter.

Best practice across the DfE construction framework: the Alliance for Learning case study | Mace Consult

Since 2011, Mace Consult has partnered with the Department for Education (DfE) to deliver more than 500 schools. A persistent challenge has been reliance on contractor-led systems for storing and managing project information, rather than a client-owned CDE.

This issue became critical in 2024 with the Alliance for Learning pilot, a strategic shift that engaged contractors earlier in RIBA Stages 1 and 2. Existing processes were no longer fit for purpose: review cycles involved up to 600 deliverables per stage, requiring uniform comment management across a multidisciplinary team of 16 experts. In some cases, Excel trackers ballooned to 6,000 comments, with an estimated 50% duplicated or outdated, often tied to different revisions, making it nearly impossible to close all comments and ensure accountability.

Mace therefore developed a comprehensive approach aligned with the Information Management Initiative Framework and 19650 standards.

The first activity during the assessment and need phases of 19650 was aligning the DfE’s Detailed Exchange Information Requirements (DEIR) to the new procurement route. This effort, based on resources developed by Bond Bryan Digital, was initiated by Mott MacDonald and completed by Mace. Following this, Mace proceeded to refine the Project’s Information Standard, Exchange Information Requirements, Project’s Information Production Methods and Procedures, and Project’s Information Protocol.

Supporting Invitation to Tender, Mace developed a Power Automate workflow to automate compliance checks, cross-referencing the DEIR, the Master Information Delivery Plan (MIDP) and deliverables in Mace’s SharePoint prior to client submission. It populates Morta and flags missing or incorrect files in real-time, reducing manual input by 50% and ensuring fully compliant submissions.

For Tender Response, Mace introduced an assessment tool to evaluate bidder responses, ensuring fairness and consistency now adopted as a standard across the framework.

During the appointment and mobilisation activities, Mace aligned principles for integrating the contractor’s CDE with Morta, ensuring ISO-compliant revisions, folder structures and metadata.

Mace implemented a multi-layered compliance system supported by automated checks and structured reporting. Documentation is verified through Morta, while alphanumeric and geometric information are checked using Solibri rules and a COBie validation tool. Results are compiled into detailed reports showing compliance percentages and failed items for rapid resolution.

Results include contractor compliance surging from 49% at RIBA Stage 3 and 58% at RIBA Stage 4 to an average of 99% across the framework.

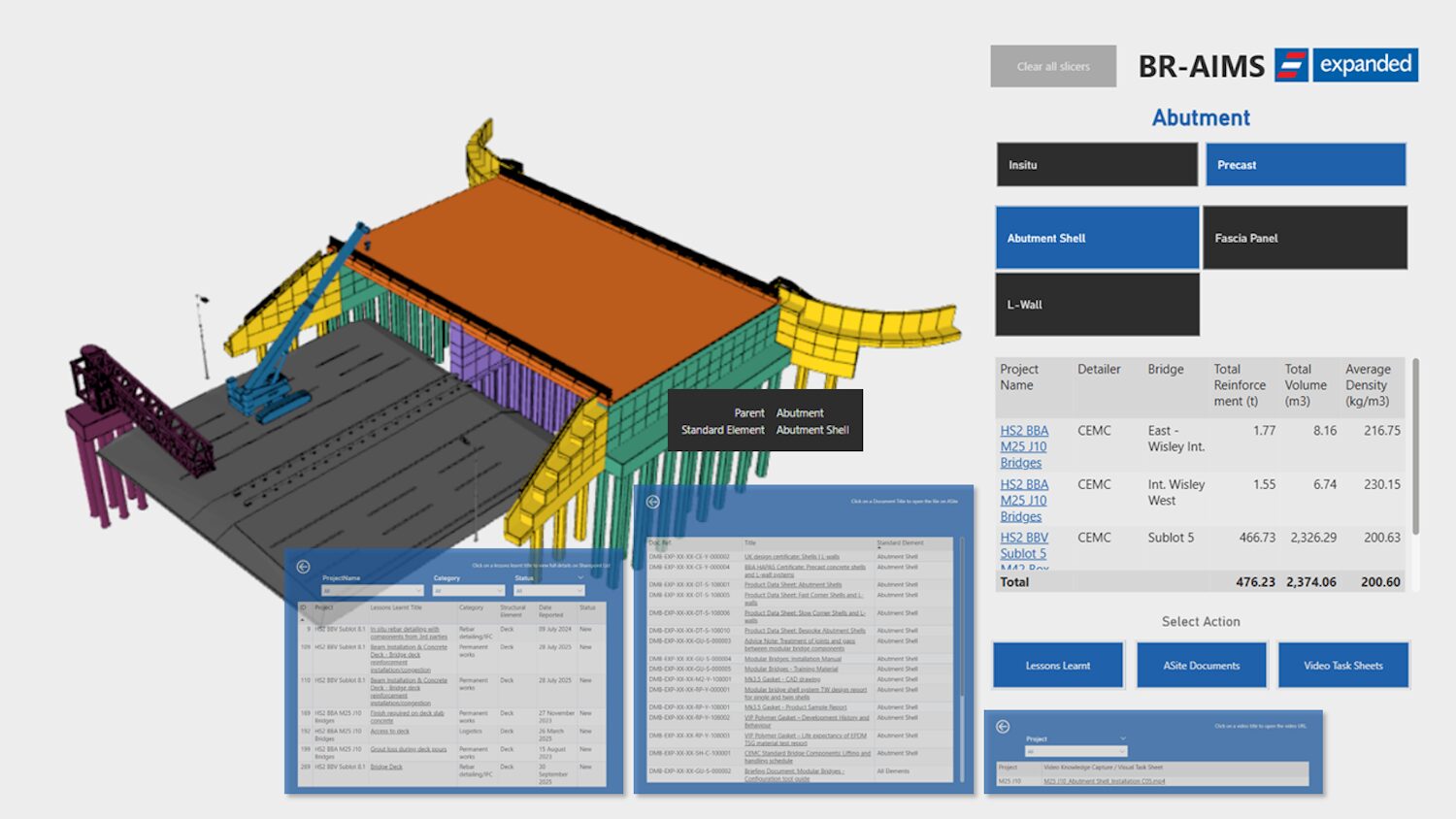

Bridge asset information management system | Laing O’Rourke

Across Laing O’Rourke’s expanding portfolio of bridge projects, teams faced a persistent challenge: while a wealth of technical knowledge and project data existed across multiple delivery sites, there was no unified, structured way to capture and reuse this information. Lessons learnt, construction documentation and visual task sheets were often stored in silos, meaning valuable insights were lost once a project concluded.

Thus, the contractor established a Bridge Asset Information Management System (BR-AIMS): a centralised Power BI environment, aligned to ISO 19650 principles, that consolidates structured data from multiple bridge projects into a consistent digital framework.

Instead of trawling through folder structures or navigating complex CDEs, users are presented with a 3D representation of a modular bridge. Interactive elements allow users to select specific components, automatically filtering and displaying documents or data related to that bridge element. This delivers a far more intuitive and transparent way of finding information.

Users begin by selecting a bridge section and then drill down to a specific element type. The dashboard displays average productivity and density benchmarks across all bridge projects, distinguishing between in-situ and precast works, offering instant, data-driven insights for planning and estimating.

Three integrated pop-up windows enrich the experience. The Lessons Learnt feature draws directly from a Dataverse table, which users can populate using a custom Power App, used across all bridge projects, ensuring consistent capture of issues, mitigations and outcomes. The Video Task Sheets interface provides direct links to training media and standardised installation sequences for each element, reinforcing knowledge transfer and site safety. The Asite Documents window retrieves relevant design and construction documentation, maintaining golden-thread traceability to verified sources.

Underpinning this is a data pipeline that cleans, aligns and validates data from multiple projects, ensuring consistent classification, metadata tagging and schema compliance.

Site engineers, planners and digital leads received hands-on Power Platform training to standardise how they record lessons learnt, ensuring future data feeds directly into BR-AIMS with minimal manual effort. The team has also added AI-driven intelligence using Copilot Studio to the system, allowing users to query the dashboard conversationally with the model to retrieve synthesised insights from the BR-AIMS dataset.

DfE Framework: Information Management Tracking & Validation proof of concept | XD House

To overcome the Department for Education framework’s information management challenges, XD House developed a structured, data-driven solution: the DfE Framework: Information Management Tracking & Validation initiative. The goal was to create a fully federated master information delivery plan (MIDP) that synchronised all task information delivery plans (TIDPs) across multiple design disciplines, ensured compliance with 19650 and embedded golden thread traceability within the existing digital ecosystem.

Rather than introducing a new CDE, the team adopted a ‘build on what works’ strategy, integrating Morta’s low-code data management platform with the Autodesk Construction Cloud (ACC) as a proof-of-concept workflow. This approach maintained continuity for project teams while introducing automation, validation, and enhanced governance.

A series of collaborative workshops led to the mapping of existing workflows and identified the key data points required for compliance. These were then modelled in Morta as a central data schema structured around 19650 container naming conventions.

The system automatically synchronised with ACC, capturing metadata, file status and submission history. Within Morta, each discipline maintained a live TIDP, filtered and validated automatically. These were synced into the federated MIDP, producing real-time dashboards displaying information status, dependencies and delivery progress. Initial implementation revealed data inconsistencies within legacy files and variations in how disciplines interpreted the DfE naming convention. To resolve this, the team introduced automated validation rules that flagged non-compliant file names and metadata. These issues were then reviewed collaboratively in weekly information governance meetings.

The introduction of the federated, data-driven MIDP replaced manual spreadsheet consolidation with automated synchronisation from multiple discipline-specific TIDPs. Benefits included a reduction of more than 70% – from an average of five days to less than one and a half – in the time required to compile and validate MIDPs.

Before implementation, audits revealed more than 40% of TIDPs contained missing or inconsistent data. Within three months of rollout, 100% of new information containers complied with 19650 naming conventions and DfE standards.

Digital building logbook | GS1 UK & GS1 Ireland/EcoWise

To address the challenge of fragmented and unreliable construction information, EcoWise, in collaboration with GS1 UK and GS1 Ireland, developed the Digital Building Logbook (DBL) – a standards-driven solution designed to embed globally recognised GS1 identifiers into construction information workflows.

The objective was to align asset, product and project data with the structured information management principles set out in ISO 19650, while supporting compliance with the UK Building Safety Act and emerging EU regulations.

The DBL connects every product and component to a verified Global Trade Item Number, Global Location Number or Global Individual Asset Identifier. These identifiers form digital links between design models, procurement records, and onsite installations through a CDE. Each tagged element becomes a trusted digital asset, ensuring its documentation, performance data and compliance evidence remain traceable across the entire lifecycle – from specification to maintenance and eventual deconstruction.

The DBL enables contractors, manufacturers and asset owners to capture structured, machine-readable information at the point of origin, significantly reducing the need for manual verification or re-entry. It integrates Environmental Product Declarations (EPDs) and Life Cycle Assessment (LCA) data, automatically populating sustainability and compliance fields within BIM objects.

The project team provided targeted upskilling sessions for both manufacturers and contractors, introducing training on data standardisation, identifier usage and structured metadata creation. This capacity-building ensured that all parties understood not only the tools but also the governance and accountability required for best practice.

An early challenge was that many manufacturers lacked consistent digital product information or accessible EPDs, creating gaps that initially slowed implementation. To address this, the team developed a data onboarding template that automatically validated inputs against GS1 and ISO metadata standards, simplifying the process for non-technical users. To combat multiple unconnected legacy systems across the supply chain, the team developed an open-API layer that synchronised data between the DBL and existing BIM, ERP and asset management platforms.

Digital construction and investment | National Gas/Premtech/Capgemini

Before the Digital Construction & Investment (DC&I) programme, managing asset information and construction projects at National Gas meant navigating a maze of emails, SharePoint folders, third-party tools, paper records and legacy systems. This fragmented approach resulted in poor asset data quality, slowed work and the absence of unified standards.

The DC&I Programme, delivered in partnership with Capgemini and Premtech, has rewritten that story. For the first time in National Gas, asset information now flows through a unified, digital-first environment that simplifies processes aligned with 19650 standards and redefines how National Gas works.

Asset data across the pilot sites was digitised and enriched, creating integrated 3D models linked to systems like Maximo and Autodesk Tandem. A comprehensive asset attribution matrix and common component library were established, ensuring consistency and scalability. For the first time, National Gas teams can trust the single digital source of truth.

19650 standards are now embedded in commercial contracts alongside robust information requirements. These provide a clear structure for project planning and visualisation, enabling teams to map out projects in detail before they even reach Autodesk Construction Cloud. This has been transformative, driving significant efficiency savings by reducing ambiguity, rework and delays. Overall, DC&I rebuilt standards aligned with ISO norms, automated 70% of manual steps and digitised numerous trackers and workflows, dramatically improving project delivery.

Structured folder hierarchies and role-based access have empowered more than 150 trained users, while Power BI dashboards deliver real-time reporting and governance. This transparency fosters a culture of collaboration and informed decision-making, breaking down silos and enabling smarter working.

From planning and design through construction, maintenance and decommissioning, DC&I introduced pragmatic and effective digital twins, metadata integration and automated workflows. The result is a safer, more compliant and future-ready operation, primed for low-carbon technologies and evolving regulatory mandates.

DC&I has achieved up to 20% faster project scoping and closeout, with projected efficiency gains of 10-15%.

The programme has moved into its scaling and optimisation phase. The focus is now on data migration and expanding deployment across the wider portfolio, ensuring that the benefits already realised are embedded and extended enterprise-wide.

HS2 Area North BIM team IFC processing | Balfour Beatty Vinci

As the main works civil contractor for HS2 Area North, Balfour Beatty Vinci’s (BBV) BIM team has to deliver structured, high-quality openBIM data. A key focus of its work is ensuring all 3D model information is correctly categorised and organised to support efficient data consumption in the operation and maintenance phase.

BBV’s challenge was to deliver several thousand digital infrastructure assets as IFC4.3. These assets were varied, complex and housed in secure environments requiring offline validation and strict data governance. As IFC4.3 was newly released, industry support from common software was still developing, so BBV decided to meet the challenge in-house and leave a positive legacy.

The team’s approach prioritised an autonomous and scalable process to normalise outputs from source applications, implement data standards, evidence compliance against a suite of Information Delivery Specifications (IDS), and comply with buildingSMART validation.

There were numerous key challenges, including learning the IFC schema and IDS definition, correcting non-compliant IFCs from sources, minimising CAD licensing costs and having limited IFC editing capabilities. The team also needed to find a way to process large IFC files, integrate complex CDE systems and improve processing outcomes.

BBV created AI-developed Python scripts to build an automated pipeline, using Microsoft Fabric, to industrialise IFC normalisation and validation. The process progressed non-compliant IFC2x3 models to fully assured IFC4.3 outputs to meet the appointing party Exchange Information Requirements. BBV developed a custom-built IFC application (Viper) to manually edit any IFC outputs that could not be processed automatically.

Initially, Fabric’s limited memory caused time-outs when processing large IFC files. To overcome this, BVV re-engineered its scripts to process files in segments, clear memory between operations and complete entity mapping without crashing.

BVV tackled the challenge of reading and modifying IFC and IDS files from Azure Blob Storage. After extensive trial and error, BBV code successfully enabled communication between Fabric and Azure, allowing seamless file handling.

Dashboarding solutions were introduced to improve transparency, script execution times, success and failure rates, and overall workflow health.

Outcomes have been transformative. Validation and classification tasks now take minutes instead of hours. Offline validation and cryptographic access control ensure full compliance with data protection policies. Reliance on expensive commercial tools and supply chain resource requirements has been eliminated. Data quality has improved through early detection of non-compliant files, as well as sustainability through reduced cloud dependency. Dashboarding has improved monitoring and accountability.

Project Colin: rethinking the approach to documentation | RLB Digital

RLB Digital’s Project Colin addresses the elephant in the room when adopting a data-driven approach: documents.

Traditionally, documents are created as large, disconnected files, O&M manuals, health and safety files, fire and emergency files (FEF), each authored by different people, in different formats, often with overlapping or conflicting content. This fragmented method leads to duplication, inconsistency, and information that’s hard to find, trust, or maintain. Editing one part without affecting others becomes nearly impossible.

Project Colin proposes a shift: instead of starting with whole documents, the process starts with individual pieces of information. These are combined to produce O&M, health and safety and FEF outputs. Each piece of information exists only once, but is reused many times. This eliminates duplication across structured and unstructured formats and clarifies what the information is, so it’s not provided twice (eg asset register vs COBie).

The process separates purposes, information requirements, task/master information delivery plans (TIDPs/MIDP) and CDE metadata. These are directly connected to the project’s information standard, where all pick lists are documented. This ensures consistent values across the workflow and aligns the CDE setup with the structure of the requirements and delivery plans, creating a unified data environment. A key challenge was transferring data from information delivery plans to the CDE. While multi-select lists worked well for building requirements, they complicated data exchange via CSV/XLSX.

To resolve this, the requirements were rebuilt using single-select lists, which was time-consuming but essential for a smoother, integrated process.

This approach enhances how information requirements are defined and tracked, from initial purpose to final delivery. Information is no longer buried in documents but becomes visible, traceable, checkable and manageable.

It allows handover documentation to begin forming even before information is produced, creating a joined-up process that reduces waste, removes ambiguity, and improves the quality of what’s handed over. This connects level of information need (ISO 7817-1) with ISO 19650 processes and aligns with PAS 1958 principles.

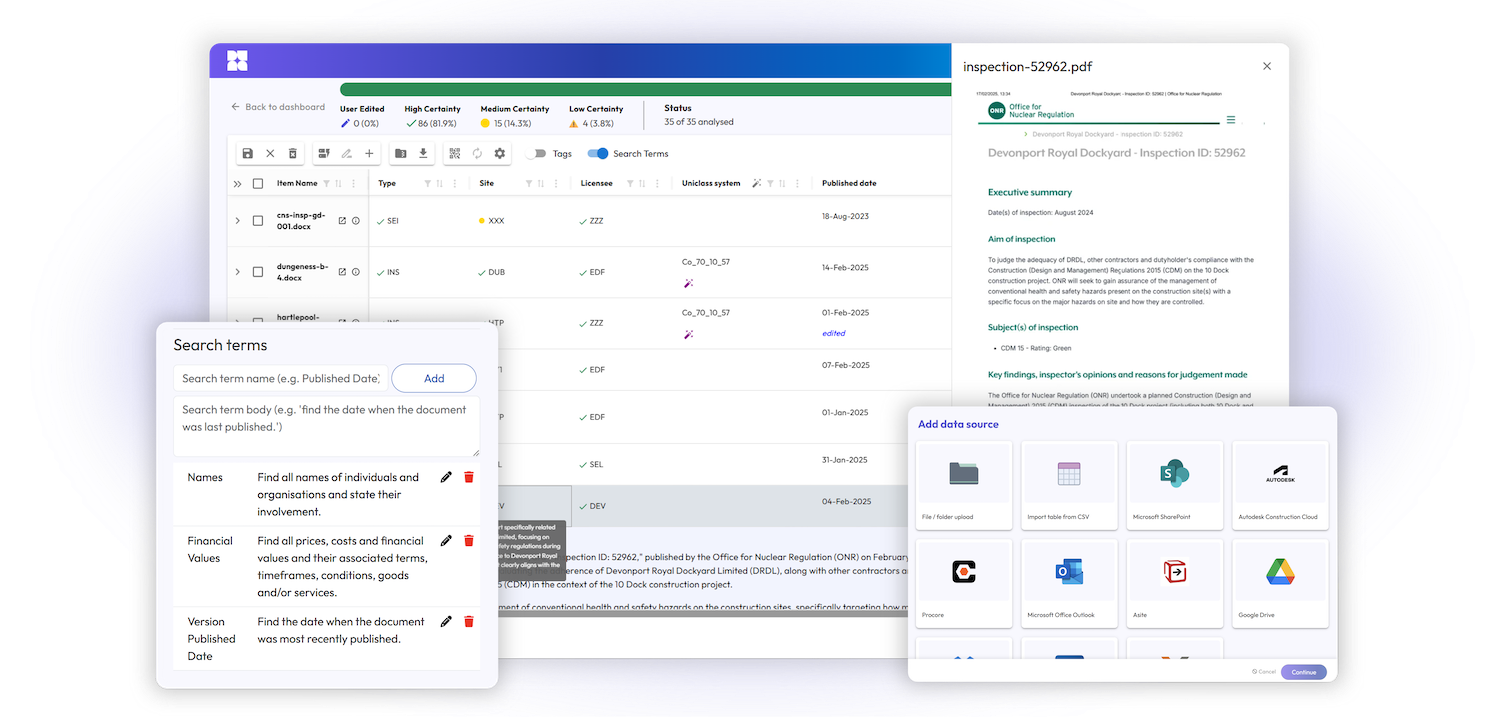

Scaling information management in the AI era | Hoppa/AtkinsRéalis

Asset owners can spend months tracing critical information, forcing teams to resurvey, redesign, or proceed with uncertainty. The result is overruns and safety risks. Yet effective data governance at scale is often impossible. During one nuclear project, AtkinsRéalis found full remediation would take 15-20 years. On another design-and-build tender, information management tasks were forecast to consume 40% of engineering time.

With remediation costs so high, AtkinsRéalis identified pilot opportunities to leverage AI to augment human information-management specialists and apply governance.

Working with Hoppa AI (a UK startup specialising in AECO data translation, classification and governance), the project focused on the demonstration of value for a large-scale (tens of thousands of documents) application on a nuclear decommissioning project, and a small-scale (thousands of documents) application for a design-and-build tender response in the water sector.

Starting with the nuclear decommissioning project, AtkinsRéalis and Hoppa adopted a human-in-the-loop AI approach combining:

- ISO 19650-compliant metadata specifications and analysis workflows;

- natural language processing and other AI-based tooling, including from industry-specific file types (Inventor, AutoCAD);

- AI classification and labelling systems, vector similarity, inductive reasoning and more; and

- human-in-the-loop validation.

Hoppa’s kit-of-parts workflow engine (Workbench) enabled the team to tailor client solutions faster, while a cross-domain approach bridged information siloes.

The pilot was conducted in a live project setting, tested and hardened on short iteration cycles. Human oversight ensured scale and accuracy. The result is that a trained, Hoppa-enabled operator completed a data-cataloguing exercise 100 times faster.

The capability was then deployed on a smaller-scale water pipeline tender, processing thousands of records. What would have taken six weeks manually was completed in three days.

The solution is now being applied for a major aviation authority. AtkinsRéalis and Hoppa are processing legacy asset records to extract key details. This data feeds an insights engine to help predict issues before they arise.

The AI-enabled approach to data mining and classification turns data into long-term business assets. Measurable benefits include:

- a 90% reduction in time classifying and cataloguing historical documents;

- 10 times improvement in data retrieval and quality validation;

- thousands of human hours saved; and

- increased confidence and compliance, with every AI-derived classification traceable and verifiable.

Making best practice inevitable in information management | Shape Construction

Shape Construction’s challenge was to close the gap between intention and execution – to create a site-first information management model that embeds best practice into the daily behaviours of delivery teams, not just into back-office systems.

Its goals were ambitious:

- to create structured, traceable records of every delivery and change event;

- to ensure all site information was captured and audit-ready without added effort; and

- to enable commercial, planning and operational teams to work from a single, real-time data source.

The Shape platform operationalised 19650 best practice by making it invisible. Instead of training site teams on information management standards, Shape embedded those standards into the tools the teams already needed to do their jobs.

Every action – whether logging a shift report, flagging an issue, or communicating with a subcontractor – automatically generates structured, time-stamped, traceable data. The platform’s key modules work together in one unified workflow:

- Shift Manager – daily site diaries linked to activities, resources, photos and location;

- Weekly Work Planner – planned work directly tied to the master programme;

- Issue Tracker – live issue capture with resolution status and ownership;

- Channels – secure project communications with full audit history; and

- Control Room – a single view of emerging change signals, linked to downstream impact.

Shape’s dashboards ensure completeness, while weekly PPC metrics align delivery to plan. Commercial teams can retrieve any record at any time, with evidence linked to every decision, preserving the golden thread of information from site to boardroom.

Contractors like Balfour Beatty and Kier rolled out the system across projects with no formal training.

In 2025, the platform generated:

- 14,000-plus structured, time-stamped records, each tied to a specific activity or change;

- 500-plus shift reports completed via mobile, automatically producing compliant daily logs;

- 77% faster issue resolution, reducing delivery risk and unlocking delayed work; and

- 15% gain in weekly plan adherence, via measurable PPC tracked across teams.

On one major programme, the commercial director recovered millions in disputed margin using Shape’s audit trail, without needing to reconstruct a single timeline manually. Another client resolved 2.5 months of delay entitlement with three exported reports: no claims consultant was needed.

Celebrate with the best

The winner will be revealed at the gala dinner at the London Marriott Grosvenor Square on 18 March. You can join the shortlisted entrants by booking your seats at the awards.

The Digital Construction Awards are organised by Digital Construction Week, the Chartered Institute of Building, CM and Digital Construction Plus. Bluebeam, nima and Sage are among the sponsors.

To find out more about the awards, head to digitalconstructionawards.co.uk.

To become an awards sponsor, email Karolina Orecchini.

Keep up to date with DC+: sign up for the midweek newsletter.