Three businesses have made the shortlist for Digital Contractor of the Year at the Digital Construction Awards 2026.

This category rewards the contractor – main contractor or specialist – that has demonstrated excellence and transformed their business through the adoption of information management best practice, digital methodologies and/or technologies.

Here are the three entries on the shortlist.

McAvoy

McAvoy’s dual role as contractor and manufacturer comes with a unique set of complex challenges that few traditional contractors face. The company’s information environment had become fragmented: project data was being generated across multiple systems, stakeholders and delivery stages, but it was often inconsistent, siloed and difficult to use.

To tackle these challenges, McAvoy implemented a holistic digital strategy designed to unify design, manufacturing, logistics and site delivery into a seamless and data-driven ecosystem. The company adopted Procore as its single source of truth, embedding 19650-aligned processes across the platform. Metadata workflows were automated to ensure consistent file structures, reliable records and full auditability.

By extending Procore into manufacturing and logistics, McAvoy created a digital thread that connects design, factory and site delivery, far more than a standard document management system. This approach is a proprietary workflow developed in-house, tailored to the specific requirements of industrialised modular construction.

Its digitally enabled design for manufacture and assembly process was integrated into Procore, and the company is now launching Power BI dashboards powered by Procore analytics.

A key advancement was the introduction of a federated digital model linked to a live bill of materials (BOM). McAvoy’s module innovation development standardisation team has driven a 20-30% increase in factory productivity through optimised workflows, digital BOM and refined scheduling.

This automation eliminates manual data entry, reduces material waste and improves cost forecasting. Integration with Procore ensures all teams work from a single, up-to-date dataset, strengthening traceability and programme certainty.

McAvoy also invested in staff training and embedded a clear digital standard: early resistance was addressed through practical support, communication of benefits and celebrating early wins.

One of the most significant shifts has been the creation of a continuous improvement cycle. Insights from dashboards and project reporting are fed back into design and manufacturing, ensuring lessons learned on one project immediately benefit the next. This accelerates optimisation across multiple schemes.

Through this integrated digital framework, McAvoy has evolved from a contractor with fragmented data into a digitally enabled contractor manufacturer, demonstrating how industrial construction can be powered by real-time analytics.

McLaren Construction

McLaren Construction faced the challenge of integrating, standardising and accelerating its approach to delivery for clients in a way that is compliant with building safety regulations, identifying the right skills for a project, and helping to create a golden thread of information that can be tracked from the beginning to the end of the project.

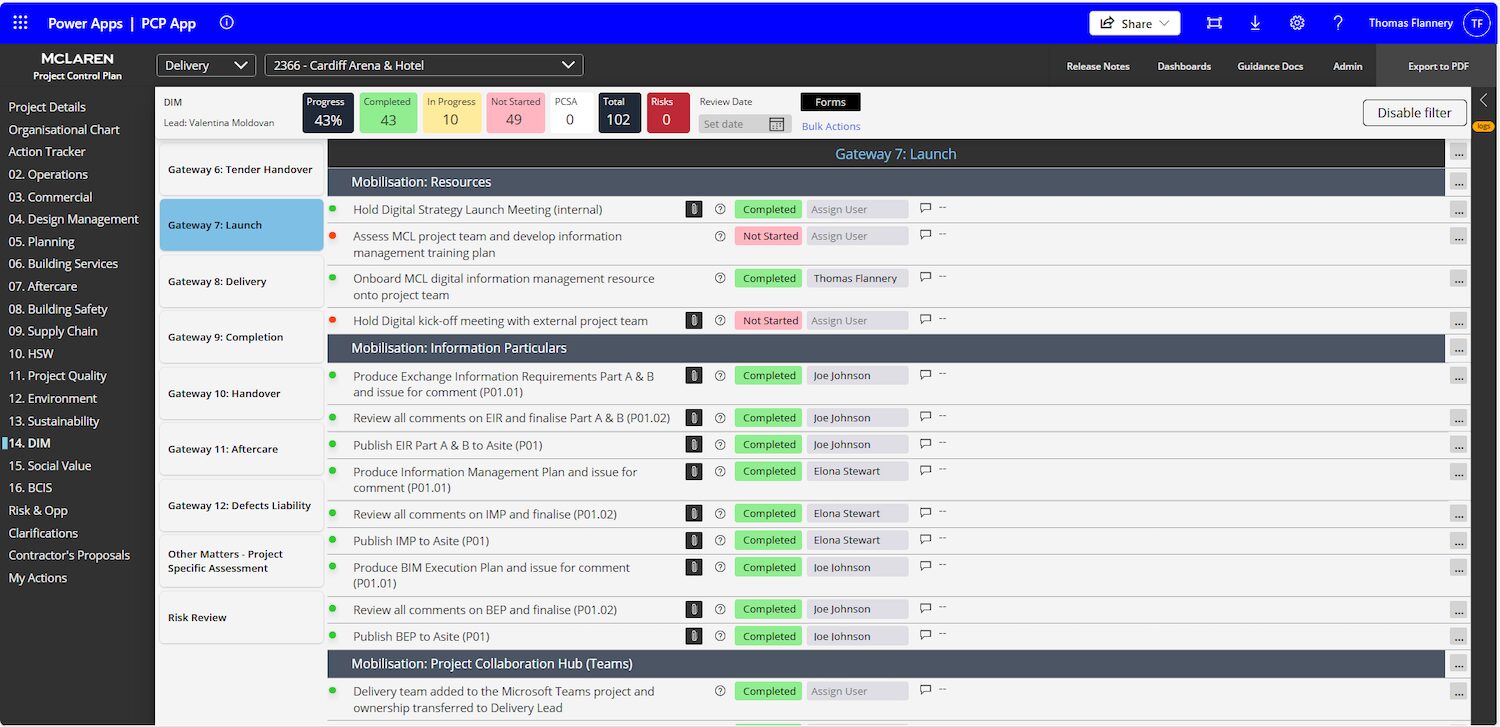

To overcome these challenges, and as part of an upgrade to McLaren’s business management systems, the contractor’s digital information management team developed an internal project management application, the Project Control Plan (PCP), to support a drive for improved efficiency via a standardised approach to project delivery.

The PCP acts as the primary application for the project team, providing a baseline for project delivery through activity schedules, acting as a single source of truth for management of risk, and providing an overview of the project team’s competency. It also integrates with other core platforms through the data lakehouse (Microsoft Fabric), surfacing key reporting metrics to improve decision-making at all levels of the organisation.

The PCP is a digital project governance system that serves as the principal document for the management of all McLaren projects from tender to handover. It identifies overarching strategies to be adopted and articulated regarding communication, responsibilities and accountability and risk management, ensuring successful and profitable outcomes for McLaren.

By deploying the PCP and integrating it with McLaren’s operational software and associated data and insights, McLaren is ultimately looking to deliver improved project certainty – time and cost – and a standardised and digital way of winning new work, including monthly project reporting.

As a result of implementing the PCP, McLaren is now able to access a group turnover tracker digitally, which includes a live pipeline conversion report. The contractor can also assess skills requirements in a pre-construction workload tracker, which helps plan training or hiring long before the project starts on site, minimising disruption or delays due to lack of skills availability.

When fully deployed across McLaren’s project portfolio, the PCP is expected to provide the company with annual savings of around £1m through refined reporting structures, bringing efficiency and productivity gains.

Robertson Group

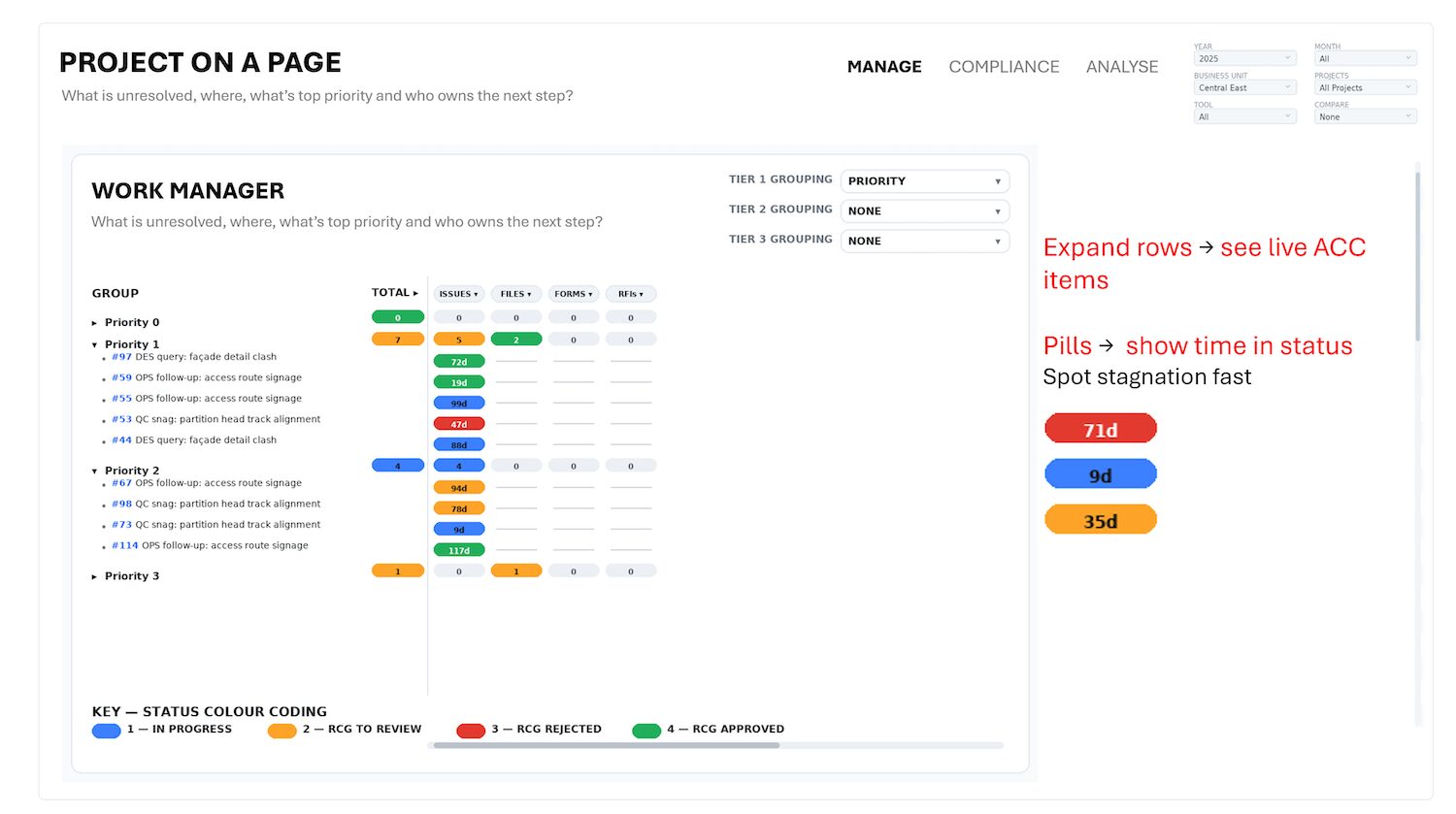

In January 2025, Robertson Group initiated a business-wide lessons learned review to enhance operational efficiency and drive future success. As part of this review, the digital construction team identified areas to strengthen digital issue management to better protect programme and cost, including risk capture, clarity of ownership and closure, serious issues not surfaced or escalated, and reporting.

The contractor required a digital-first solution that would be adopted across the business and wouldn’t be seen as a niche initiative from the digital construction team. It was therefore led by Robertson Group’s executive technical services and executive operations directors with board backing.

The contractor retained the Auotdesk Construction Cloud (ACC) Issues module as its single platform of choice, because the gap lay in procedures and configuration, not the software. It expanded issue management from a quality-only focus to comprehensively cover all causes of programme delay, including design, SHE, logistics, interfaces, client actions and third-party approvals, among others.

Co-designing the new issue type set with function heads, the team agreed on what should be raised, who owns it and how it should flow. It mandated a single, standardised list of issue types across all business units, replacing local variations and legacy lists.

It also introduced a mandatory impact and priority field on every issue type, using a five-level scale from 0 to 4, and developed simple definitions and real project examples for each level. Executive directors led in-person training briefings in all regional offices, explaining how the impact system links to project reviews and board reporting.

To ensure ownership through to closure, the team created and systematically launched a new issue management procedure to achieve formal governance for ACC issues. For wide adoption, it was added to the project management section of the company’s management system, not the digital construction section.

The procedure defines supply chain roles responsible for each issue type. Previously, specific individuals in the supply chain were assigned issues. Now, new standard ACC roles must be used when assigning issues to the supply chain, mirroring Robertson’s standard work package list.

To automate reporting, Robertson enhanced the standardised ACC reports list by adding priority-focused reports. Now, priority 0 and 1 reports are emailed daily to accountable roles and senior management, while priority 2 reports are sent every three days. Power BI dashboards are in advanced development. Priority-based live reporting concepts have been presented to the board and to Robertson’s Power BI experts, with completion scheduled in late 2025.

Celebrate with the best

The winner will be revealed at the gala dinner at the London Marriott Grosvenor Square on 18 March. You can join the shortlisted entrants by booking your seats at the awards. There is an early bird discount for those who book tables by close of play 23 January.

The Digital Construction Awards are organised by Digital Construction Week, the Chartered Institute of Building, CM and Digital Construction Plus. Bluebeam, nima and Sage are among the sponsors.

To find out more about the awards, head to digitalconstructionawards.co.uk.

To become an awards sponsor, email Karolina Orecchini.

Keep up to date with DC+: sign up for the midweek newsletter.