Nine great ideas have made the shortlist for Product Innovation of the Year at the Digital Construction Awards 2026.

This category focuses on new technology – hardware or software – that has been on the market for no more than 18 months. We welcomed entries from startups through to major suppliers, and from across the built and managed environment supply chain.

The judges looked for evidence of genuine innovation, not a me-too product, that has the opportunity to bring about real-world improvements in the delivery and operation of the built environment.

Here are the nine product innovations that made the shortlist.

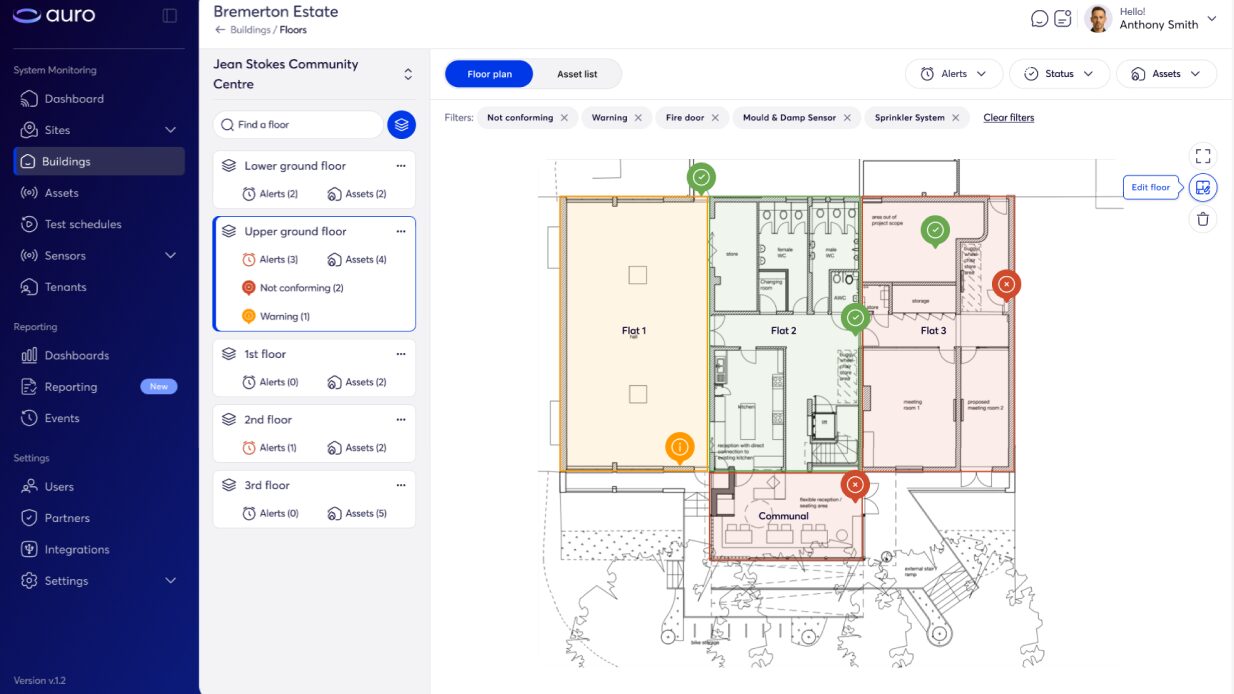

Auro Door | Harmony Fire

Fire safety engineering consultancy Harmony Fire developed a fully integrated, IoT-enabled and certified fire door system that provides real-time, 24/7 compliance monitoring. The “world-first” Auro Door was created in response to the multiple challenges of compliance, effective asset management and golden thread requirements in the social housing sector.

Auro Door embeds a long‑life, battery‑powered suite of sensors within doors that measure gap, swing and drop to 0.1 mm, and detect slams and abnormal motion. Upon installation, the sensor self-validates the door’s tolerance. The door cannot be signed off until this check passes.

Continuous data is streamed via LoRaWAN to Auro Door’s dashboard, triggering instant alerts for deviations, prolonged inactivity or forced entry. Harmony Fire spent around £4m in the three-year development of Auro Door, which involved extensive fire testing, new manufacturing processes and upskilling installation teams.

Trials with social landlords have shown compliance data instantly available, eliminating manual inspections and reducing budgeting uncertainty for repairs. Landlords reported predictive maintenance, avoidance of unnecessary door‑closer replacements and enhanced resident safety.

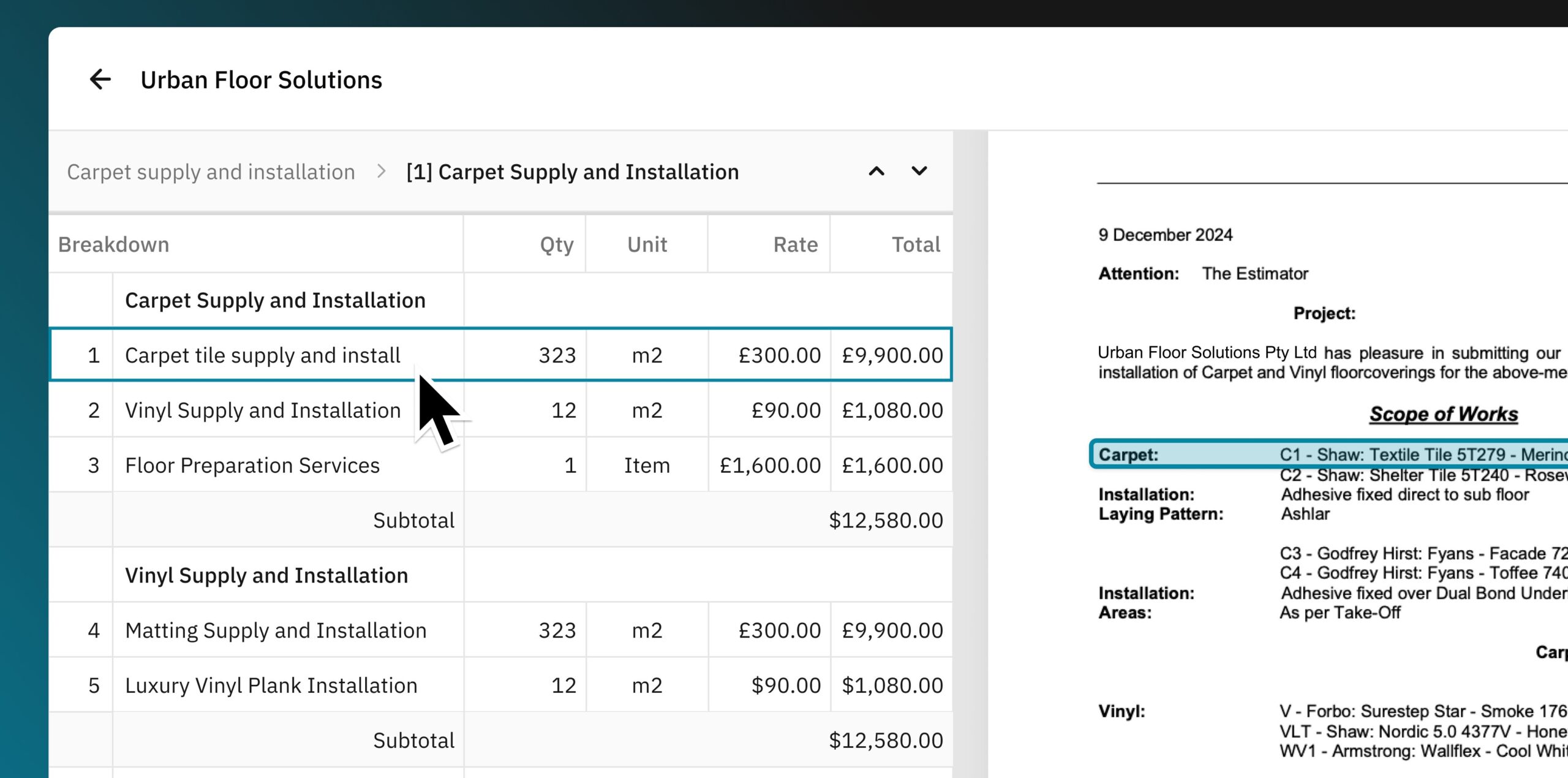

BidLevel | ProcurePro

Procurement software platform ProcurePro created BidLevel to tackle one of the most labour-intensive steps in pre-construction: levelling vendor quotes. Estimator teams traditionally spend hours copying data from dozens of differently formatted pdf quotations into spreadsheets, which is both time‑consuming and prone to error.

BidLevel was built as a vertical-specific AI platform that extracts, standardises and aligns pricing data directly from the original pdfs into a clean, comparable view. The system retains extracts and aligns line items, surfaces inclusions and exclusions, and produces an ‘apples-to-apples’ comparison in minutes.

BidLevel incorporates:

- structure‑aware pdf parsing to preserve cell‑level context;

- construction‑tuned language models trained on real‑world quote data from ProcurePro;

- confidence markers and editable mappings so estimators can verify and adjust outputs without losing speed; and

- an audit‑ready trail that supports award rationales and downstream handover.

Across live deployments, BidLevel has reduced the time required for quote levelling by up to 80%, converting a multi‑hour manual task into a 60‑second extraction and a 60‑second comparison per package.

Users report faster tender reviews, earlier identification of inclusions and exclusions, and fewer overtime spikes near deadlines. The automated workflow also eliminates duplicate data entry, improves estimate accuracy and provides a single source of truth for supplier pricing, ultimately increasing bid capacity without additional headcount.

Leica TS20 | Leica Geosystems

In October 2025, Leica launched the TS20 robotic total station: a ground‑up redesign that brings the first AI‑enabled, IP66‑rated surveying instrument to the construction market.

Surveyors face three persistent barriers to accurate, millimetre‑level measurements, including:

- human error – mistakes that now account for around 11% of UK construction costs;

- site conditions – obstructions, mist, rain, dust and frequent line‑of‑sight loss; and

- equipment theft, which costs UK firms around £1bn annually.

Existing total stations lack the intelligence, weather resilience and security needed to mitigate these risks, Leica states.

Thus, it equipped the TS20 with a dedicated neural processing unit that runs AI algorithms trained on thousands of real-world surveys, including wet weather data collected in Wales. The AI automatically identifies target type, validates offsets and recognises partially obscured prisms or tape targets.

An IP66 enclosure protects the device from heavy rain, sandstorms and dust. Future firmware adds AI‑driven relocking to the Leica AP20 smart prism, instantly reacquiring line‑of‑sight after obstructions. Integrated IoT connectivity provides smart locating, remote locking and tamper detection, while cloud sync enables instant data transfer between field and office.

AI-powered target recognition and searching, combined with new electronic distance measurement and motors, deliver around 30% faster measurements than previous models and up to 25 distance measurements per second, allowing more work in less time.

Its weatherproof design eliminates downtime caused by rain or dust, and theft‑deterrence features protect equipment. Better mobile and cloud connectivity enables easy data flow between field and office teams, allowing office crews to review measurements immediately and catch potential issues before they escalate into expensive problems. This also means surveyors in the field have the most up-to-date plans.

Real-time collaboration reduces delays caused by manual data transfer and improves decision-making across projects.

NavLive

NavLive was created to eliminate the longstanding bottleneck of slow, manual data capture in construction and surveying. By combining LiDAR, high-resolution photography and on-device AI, the system delivers floorplans, elevations and 3D point clouds in minutes.

Traditional surveying workflows require days of onsite work and extensive cloud processing, producing outdated as‑built information, project delays and higher costs. Existing alternatives either depend on expensive specialist hardware or cloud services that limit real‑time control of data.

The NavLive scanner integrates LiDAR, a high‑resolution camera and an NVIDIA Jetson edge computing module. Proprietary AI fuses the sensor data on‑device, generating lightweight outputs that can be viewed instantly and fed directly into BIM workflows.

The device is deliberately simple to operate, making it usable by professionals with varied technical backgrounds while still meeting the precision needs of surveyors. Early adopters report capturing complete building data in minutes instead of days.

The on‑device processing improves health and safety by limiting repeat site access and supports compliance with the Building Safety Act 2022 through more accurate as‑built records. Future plans include control points integration, expanded BIM and digital twin features, as well as compatibility with autonomous robots and drones for fully automated data capture.

Quin Pod, App and Tag | Quintessential Design

Sensor technology company Quintessential Design (Quin) is redefining construction safety in the UK by turning ordinary PPE into an active, data‑driven safety network. The system combines the Quin Pod, Quin Within app, and Quin Tag to capture, analyse and share incident data in real-time.

Despite PPE being mandatory on construction sites, the sector still suffers high injury rates. In 2023/24, 31% of non‑fatal injuries were slips, trips and falls, with head injuries remaining a serious concern. Traditional PPE stops at impact: it cannot log events, trigger rapid medical response or satisfy RIDDOR reporting for near‑misses that often go unrecorded. This reactive model leaves patterns hidden and workers exposed to recurring hazards.

Quin embeds motion and impact sensors in the Quin Pod, recording up to 6,600 samples per second to detect slips, trips, falls or collisions. When a significant event occurs, the pod alerts emergency contacts and transmits location, severity and condition data. The Quin Within app logs each event, provides analytics and highlights risk patterns for site‑wide safety improvements.

The Quin Tag stores essential medical and contact information, readable via NFC even if the wearer is unconscious. The technology integrates with existing PPE brands without redesign, and its algorithms are trained on construction‑specific motion data to minimise false positives while preserving worker privacy.

Pilot sites report alerts reaching supervisors within seconds, previously unreported near misses now logged, and real-time data shaping toolbox talks and risk assessments. Faster incident notification improves medical response and RIDDOR compliance, while aggregated, anonymised data guides PPE replacement schedules, safer site layouts and future industry standards.

Revizto 5.16

Revizto 5.16 was created to eradicate the longstanding disconnect between 2D construction drawings and 3D BIM models that hampers coordination, quality control and decision-making across design, coordination and construction phases.

Until now, professionals have had to switch repeatedly between static 2D pdfs or sheets and dynamic 3D models, slowing issue resolution. Existing clash detection only flags geometric overlaps and cannot automatically verify mandatory safety components, such as fire stops or exit signage. Additionally, BIM users must build intricate search sets to isolate specific elements, which wastes coordination time.

Revizto 5.16 introduces a first-of-its-kind 2D/3D split view that synchronises a drawing and its corresponding model location in real-time, eliminating context switching. The ‘required objects’ clash test extends detection to regulatory items, automatically confirming presence and correct placement.

Built on a high-performance gaming engine of more than seven million lines of code, the platform handles massive federated models without lag, and supports four simultaneous sessions on desktop, mobile and VR. Development was driven by Revizto’s premium user group, ensuring the features addressed real-world friction points.

Since the March 2025 launch, 60% of Revizto users have upgraded, citing immediate acceleration in workflow. Early adopters report huge savings by avoiding rework, faster scheduler runs and overnight compliance verification. Future releases will add more rule‑based checks and tighter integration of operational data with as‑built models, extending the platform’s value throughout the asset lifecycle.

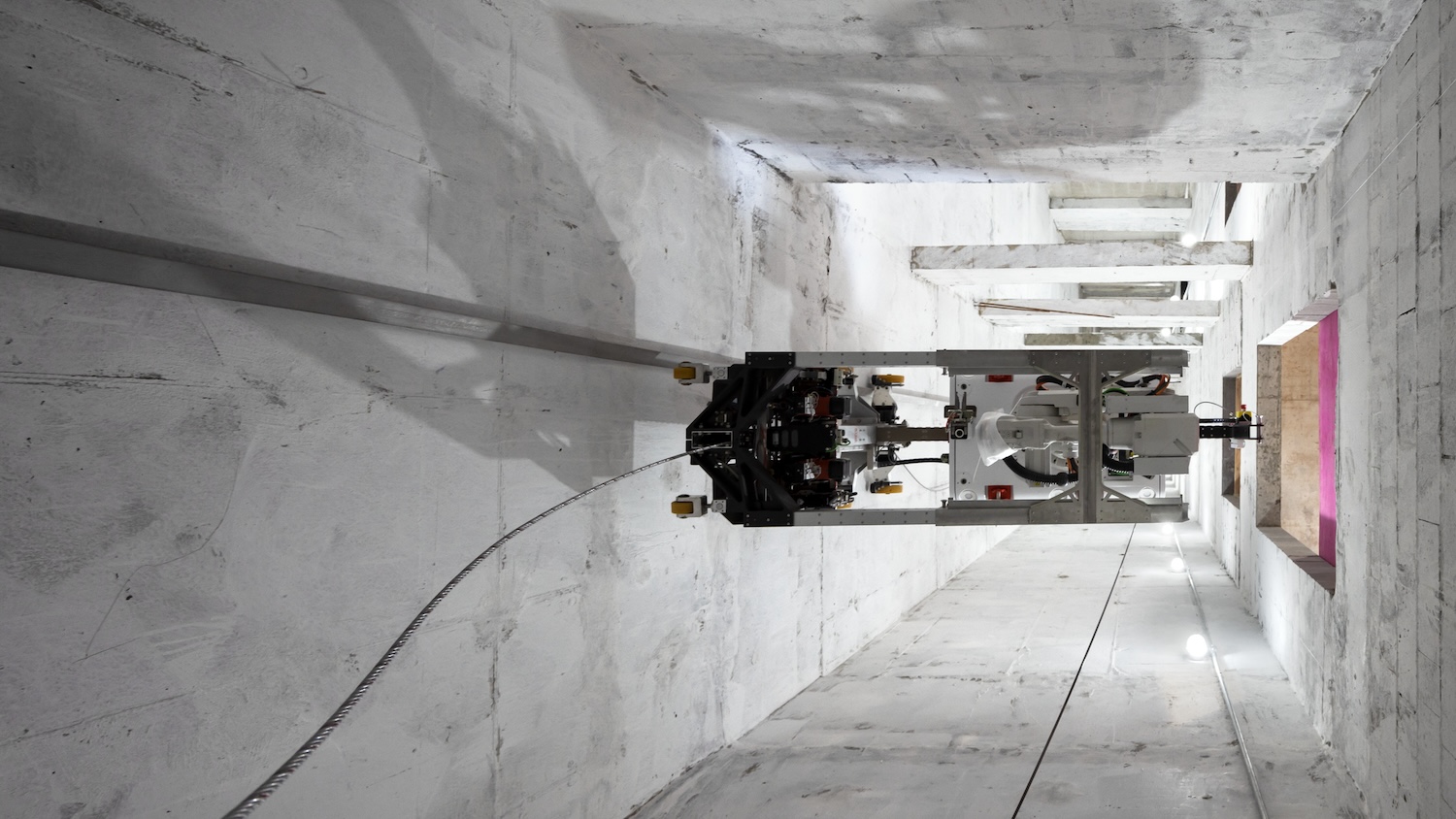

Schindler R.I.S.E

Schindler has developed the world’s first robotic installation system for elevators (R.I.S.E.): a self‑climbing robot that automates guide rail and shaft preparation work for mid‑ to high‑rise buildings.

Elevator installation traditionally requires workers to spend long periods in confined shafts, often before permanent lighting, power or environmental controls are available. The task is hazardous, time‑consuming, prone to errors and rework, and it slows overall programme schedules.

R.I.S.E. combines precision sensors, laser alignment and a digital control interface. The robot can complete a floor – drilling and setting the anchor bolts required for landing doors, divider beams and wall brackets – much faster than conventional installation methods. A camera is mounted onto the platform to allow remote viewing, but the system operates independently without the need for an operator.

The system was first deployed on Skanska’s redevelopment of 105 Victoria Street, London, where Schindler’s engineering team worked with local construction partners to adapt the robot to UK shaft geometries, standards and site logistics. Data from each installation step is automatically exchanged with the building’s digital model, supporting future construction and maintenance phases.

R.I.S.E. also improves safety by eliminating the need for workers in high‑risk shaft environments. Additionally, automation delivers consistent installation faster than manual methods, reducing rework and its associated cost.

The successful London pilot has prompted plans for further UK deployments, establishing a new benchmark for robotic, digitally integrated elevator installation.

SiteView | PlanRadar

PlanRadar’s SiteView adds fully integrated 360° photo documentation to the company’s SaaS construction‑management platform, giving more than 170,000 users in more than 75 countries a single source of truth for visual site data.

SiteView was developed to solve the problem of construction teams losing hours manually organising, tagging and cross-referencing photos, resulting in isolated images lacking precise location context. Without verified visual records, confirming work completion requires site visits, remote collaborators struggle to understand conditions, and ‘behind-the-wall’ moments are often undocumented, creating compliance and quality risks.

SiteView allows operators to attach a 360° camera to a helmet and walk the site: its AI-powered platform maps the images and plots the walk path onto a 2D plan, automatically linking each view to exact coordinates. The feature is built natively into PlanRadar, so tickets, defect reports, BIM models and progress dashboards can be pinned directly onto the 360° images.

A lightweight visual data processing system renders large visual datasets in real-time and supports cameras from multiple manufacturers, keeping the platform fast and hardware‑agnostic.

Since its launch, users have reported a 60%‑70% reduction in photo‑capture time compared to traditional methods, elimination of manual tagging and the ability to conduct virtual inspections that cut travel costs. Precise location mapping has removed ambiguity, improved audit trails and accelerated dispute resolution.

Skills Trawler | AtkinsRéalis

Skills Trawler v2.0 is AtkinsRéalis’s redesigned global skills management platform, serving a workforce of more than 35,000 employees across Europe, North America, the Middle East, India and Australia.

Before its launch in May 2025, skills data was often fragmented and inconsistent, making it difficult to locate and mobilise the right expertise quickly. Users struggled to add relevant skills, while search results were overwhelming, which could lead to delays, higher delivery risk, project overruns and underused talent.

The new platform introduced a guided profile editor that suggests skills based on role, network and user‑defined keywords, reducing profile update time to about five minutes. The search function was rebuilt with a best-match ranking, richer filters and a cleaner interface, surfacing the most relevant colleagues faster.

Profiles now combine top skills, development areas and contact details in a single view. Integration with AtkinsRéalis’s HR enabled AI-driven recommendations for learning, mentoring and internal opportunities, aligning personal development with organisational demand and reducing duplication across systems.

Adoption has reached 13,000 users, logging more than 800,000 individual skills. Users have reported faster shortlisting, reduced CV review time and improved compliance by ensuring only certified personnel are assigned to safety‑critical tasks.

Celebrate with the best

The winner will be revealed at the gala dinner at the London Marriott Grosvenor Square on 18 March. You can join the shortlisted entrants by booking your seats at the awards. There is an early bird discount for those who book tables by close of play 23 January.

The Digital Construction Awards are organised by Digital Construction Week, the Chartered Institute of Building, CM and Digital Construction Plus. Bluebeam, nima and Sage are among the sponsors.

To find out more about the awards, head to digitalconstructionawards.co.uk.

To become an awards sponsor, email Karolina Orecchini.