Seven great ways of making sites safer have made the shortlist for Digital Innovation in Health, Safety and Wellbeing category at the Digital Construction Awards 2026.

This category recognises the use of digitalisation, digital methodologies and/or technologies to enhance health, safety and wellbeing among workers on a construction project or projects.

Seven entries made the shortlist.

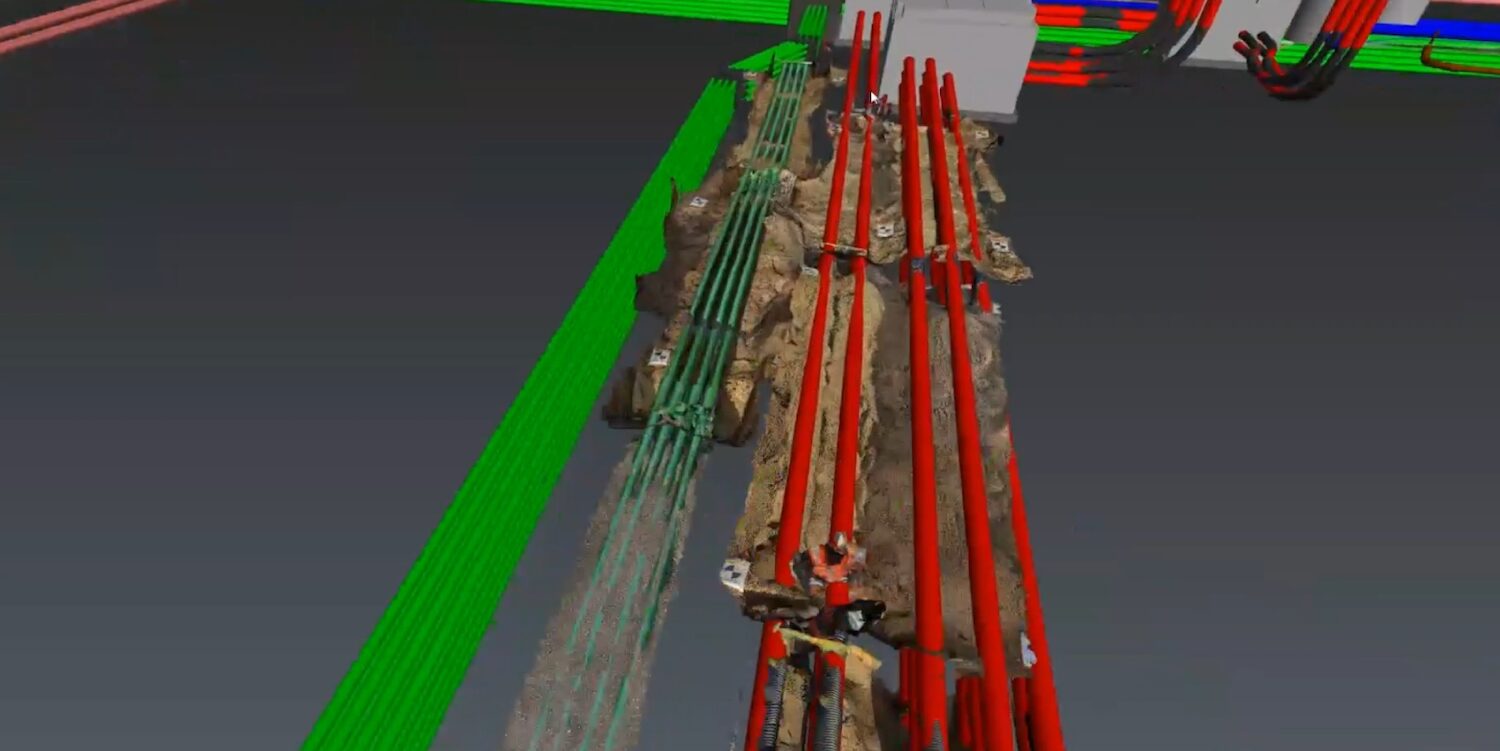

Below-ground services digital lifecycle process | Laing O’Rourke

Laing O’Rourke has introduced a digital lifecycle process for below-ground services that delivers a 3D model of buried utilities up to 75% faster than traditional manual modelling, and which has improved health, safety and operational efficiency across multiple projects.

Utility strikes remain a major hazard because service records are scattered across 2D line drawings and handwritten notes that lack accuracy and depth data. Manual conversion of these surveys into 3D models can take three digital engineers six weeks – and still leaves gaps that lead to catastrophic injuries, costly reworks and non‑compliance with permit to break ground requirements.

The in-house-developed automation tool’s script can read the survey 2D drawing provided by any surveying company. If depth data for a service is not present on the drawing, the tool recognises this and generates a hazard warning marker across the length of the service line, signifying the requirement for further investigation work before proceeding with works in the zone.

Laing O’Rourke worked closely with its subsidiaries Select, Expanded and Crown House Technologies to develop a unified, end-to-end below-ground lifecycle to deploy on projects.

The tool has been applied to eight projects since its launch and is now being mandated for future works in line with Select’s surveys. Automation is reducing modelling effort from weeks to days, delivering 70%‑80% time and cost savings.

The tool has saved an estimated total of £148,000 to date. Laing O’Rourke estimates that it will deliver £20,000 in savings per project each time new survey data is received, while significantly improving safety, compliance and operational efficiency.

Beyond the gate: redefining digital safety | Hammertech/BW: Workplace Experts

HammerTech partnered with BW: Workplace Experts to create a connected digital safety ecosystem that secures site access while scaling with BW’s rapid turnover growth from £100m to £325m-plus within a decade and managing up to 35 live projects at once.

BW’s traditional safety workflow relied on manual sign‑ins, paper inductions and isolated turnstile systems. Safety, right-to-work checks and training records were stored separately, causing duplication, friction and limited real-time visibility.

HammerTech’s integrated access control and safety management platform was linked to BW’s Procore project management system. When a project is created in Procore, it auto‑populates in HammerTech, eliminating duplicate data entry.

Operatives are identified at the gate by facial recognition tied to their HammerTech profile. Access is granted only after online inductions, credentials and competency checks are approved. RAMS, permits and deliveries are all digitised, feeding live data back into Procore diaries and logistics tools.

Among the outcomes of the new safety ecosystem are a 100% induction and approval of operatives before site entry; onboarding time down by 40% and manual log entry reduced by more than 70%. Fully digitised RAMS and permit workflows have reduced administrative time by 60% and eliminated paper-based delays.

Competent workforce = safer sites | Persimmon Homes/Construction Skills Certification Scheme

Persimmon Homes partnered with the Construction Skills Certification Scheme (CSCS) to embed live competency verification into the Persimmon Way app, creating a digital safety ecosystem for thousands of subcontractors and more than 10,000 workers across the housebuilder’s 270 developments.

Site‑management teams previously photographed, photocopied and filed each worker’s competency card in disparate systems. Fragmented data allowed expired, revoked or fake cards to slip through, creating a health and safety risk and consuming valuable time. Manual checks offered no real‑time assurance that every person on site was authorised to work.

In early 2025, Persimmon extended its Persimmon Way App – already used by 90,000 registered users for QR‑code site sign‑ins – to integrate the newly released CSCS Smart Check API.

When a worker scans the site office QR code, the app instantly validates the card’s status, expiry date and underlying training. Access is granted only to workers with a current, authentic card, and an invalid response triggers an alert for the site manager. The integration required no extra hardware, preserved the existing sign‑in workflow, and automatically logs all checks, creating a golden thread of competency evidence.

Site managers now save considerable time to focus on more valuable tasks, while workers benefit from universal and digital verification: once inducted, they don’t need to repeat checks across sites. The unified data view gives senior leadership a reliable, company‑wide snapshot of workforce competence, contributing to fewer site accidents, higher productivity and better construction quality.

Digitising site operations at scale | Hill Group/innDex

Housebuilder Hill Group partnered with cloud-based construction project management software innDex to digitise its core site operations across more than 60 live projects and a workforce of up to 5,000 daily operatives.

Paper‑based inductions, manual permit sign-offs and fragmented access control systems created inconsistent safety standards, lengthy approval times and a high administrative burden. Managers often had to travel across large, multistorey sites to authorise work, leading to delays, while tracking who was on site was unreliable.

InnDex delivered a purpose-built digital workforce and site management platform that links every step of the site‑entry process. Workers complete digital inductions and upload qualifications before arrival. Approved profiles automatically unlock turnstiles or mobile‑verification entry. Permits are created, signed and closed from a mobile device, with photos, timestamps and digital signatures, cutting approval time from hours to minutes.

Integrated facial recognition or mobile verification enforces entry only for authorised workers. In‑app messaging replaces notice boards, providing instant safety alerts with read‑receipt tracking. All data feeds a daily Power BI dashboard that shows workforce numbers, trades, permit status and site attendance in real-time.

Outcomes of this implementation include more than 360,000 inductions logged, saving the equivalent of one site manager’s day per week per site, and more than 2,700 digital permits issued, reducing approval time by up to 50 minutes each.

Additionally, instant, tracked communication has boosted compliance with safety briefs, while daily dashboards have given leadership immediate visibility for resource allocation and risk mitigation.

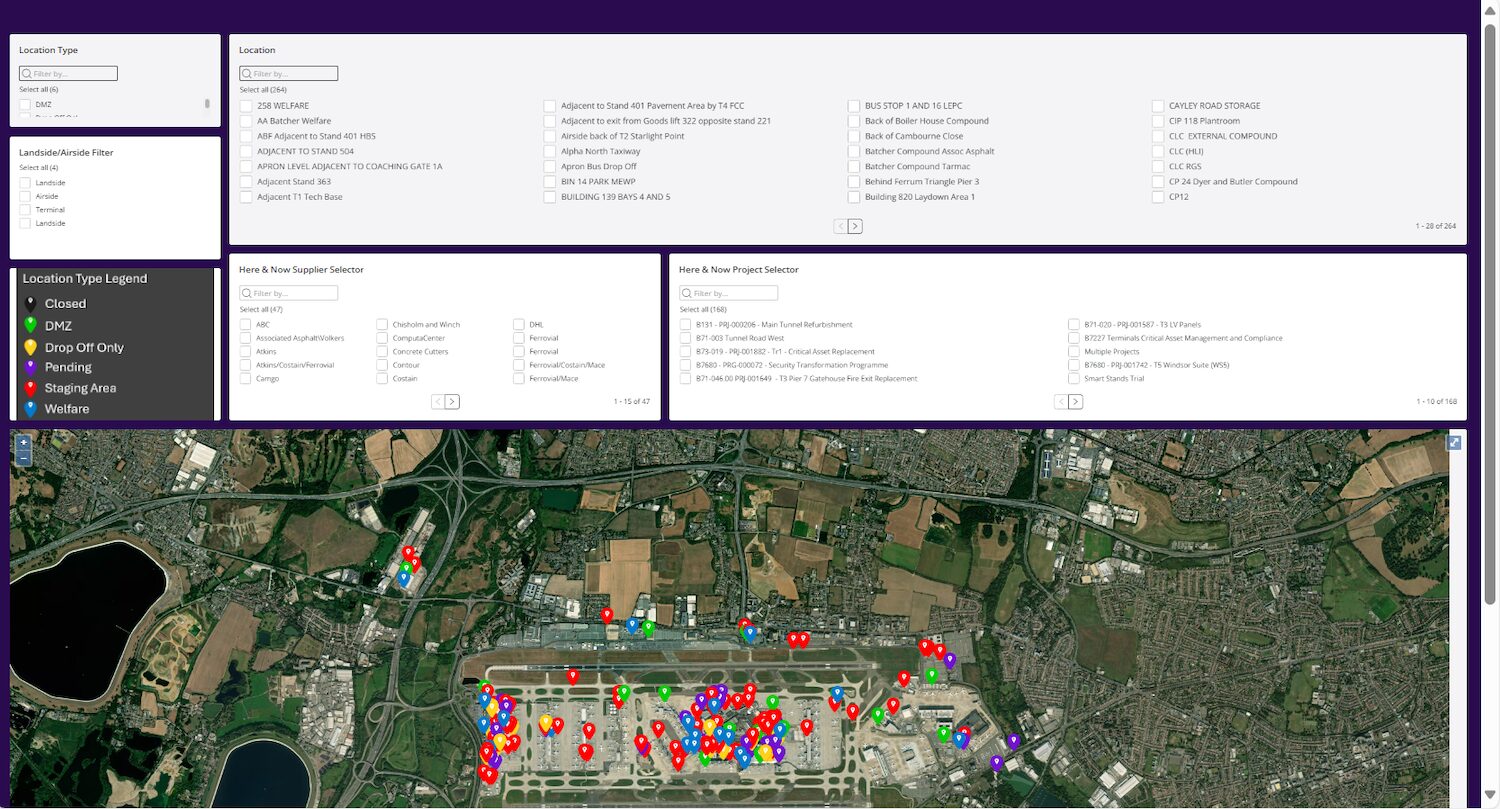

Predictive safe space management in a live airport environment | Wilson James/Heathrow Airport

Wilson James, together with Heathrow Airport’s Fulcrum Development Team, has delivered a digital safe space management system that governs more than 260 logistics sites (including welfare compounds, lay‑down zones and operational interfaces) across the live airside and landside environment.

Before this solution was implemented, Heathrow’s construction logistics were tracked on paper and managed by fragmented stakeholder processes. Limited visibility of compound locations, permit status and spatial interactions created a risk of overlapping activities, missed permit expiration dates, inefficient space use and inconsistent reinstatement standards.

Using the Fulcrum SiteMatrix platform, Wilson James built:

- a unified digital control layer that includes a digital twin of more than 260 sites, showing exact dimensions and operational boundaries;

- a collaborative safe space approvals board that reviews, authorises and monitors compound allocations and swept‑path access before activation;

- integrated permit‑lifecycle management that flags upcoming expiries, triggers renewal notifications and prevents unauthorised occupation;

- standardised startup, in‑use and closure audits recorded on the platform; and

- a real‑time oversight dashboard delivering predictive spatial awareness and route planning.

Since its launch, the system has recorded zero spatial safety breaches, achieved 100% permit compliance, and improved compound utilisation through shared welfare and lay‑down areas. Auditable digital records now feed into Heathrow’s ISO 45001 safety management system, reducing operational disruption and enhancing workforce wellbeing.

Quin Pod, App and Tag | Quintessential Design

Sensor technology company Quintessential Design (Quin) is redefining construction safety in the UK by turning ordinary PPE into an active, data‑driven safety network. The system combines the Quin Pod, Quin Within app and Quin Tag to capture, analyse and share incident data in real-time.

Despite PPE being mandatory on construction sites, the sector still suffers high injury rates. In 2023/24, 31% of non‑fatal injuries were slips, trips and falls, with head injuries remaining a serious concern. Traditional PPE stops at impact: it cannot log events, trigger rapid medical response, or satisfy RIDDOR reporting for near‑misses that often go unrecorded. This reactive model leaves patterns hidden and workers exposed to recurring hazards.

Quin embeds motion and impact sensors in the Quin Pod, recording up to 6,600 samples per second to detect slips, trips, falls or collisions. When a significant event occurs, the pod alerts emergency contacts and transmits location, severity and condition data. The Quin Within app logs each event, provides analytics and highlights risk patterns for site‑wide safety improvements.

The Quin Tag stores essential medical and contact information, readable via NFC even if the wearer is unconscious. The technology integrates with existing PPE brands without redesign, and its algorithms are trained on construction‑specific motion data to minimise false positives while preserving worker privacy.

Pilot sites report alerts reaching supervisors within seconds, previously unreported near misses now logged, and real-time data shaping toolbox talks and risk assessments. Faster incident notification improves medical response and RIDDOR compliance, while aggregated, anonymised data guides PPE replacement schedules, safer site layouts and future industry standards.

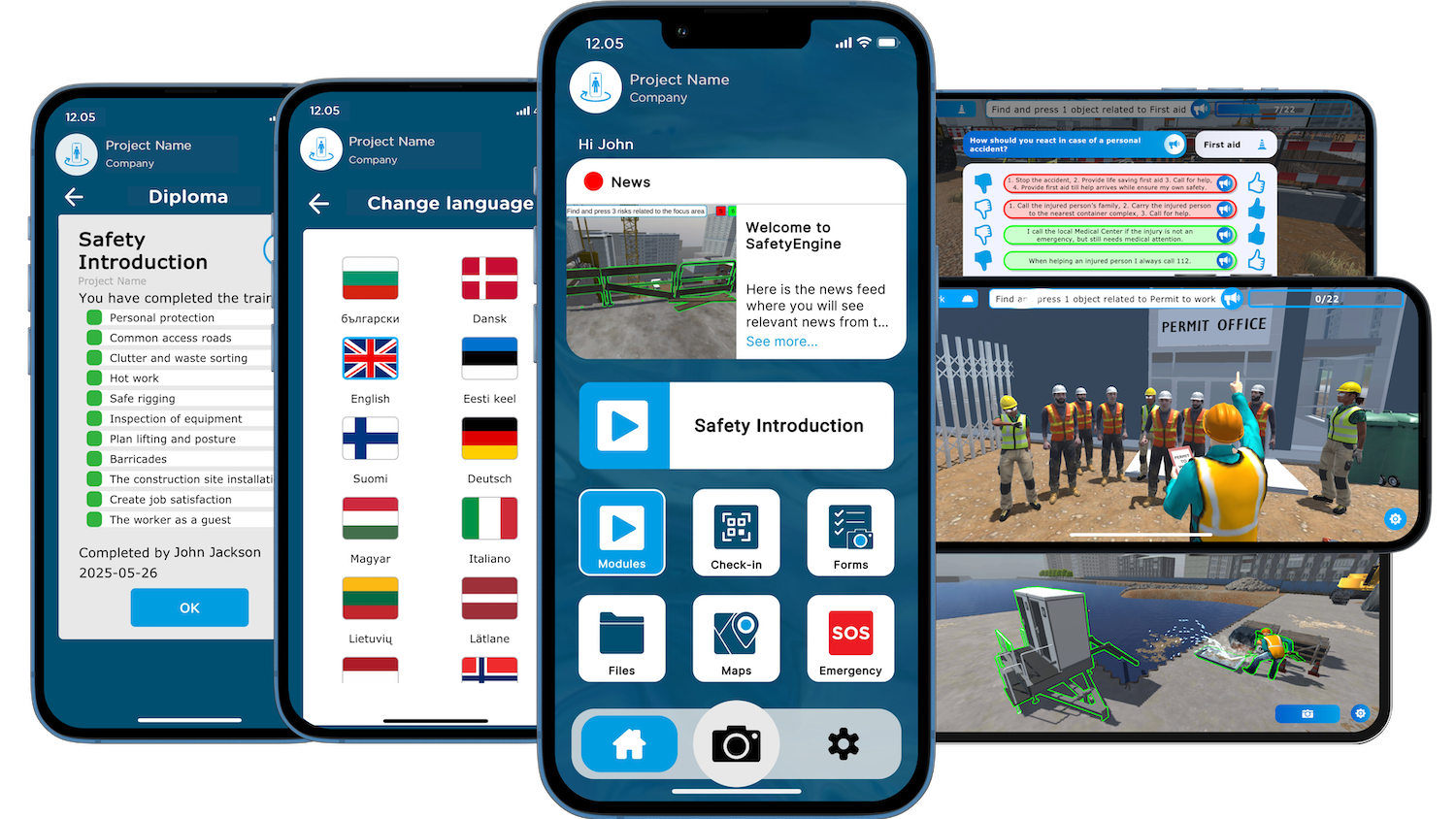

SafetyEngine | Ramboll

Ramboll’s SafetyEngine is an immersive learning platform that turns health and safety training into an active, gamified experience. The platform was launched to address the high accident rates in construction, and is now a solution used by more than 30,000 users across the construction, pharmaceutical and education sectors.

Ramboll partnered with health and safety experts and client teams to embed behavioural science principles in a 3D environment that can be accessed via web or mobile app in more than 20 languages. The platform combines scenario‑based simulations, real-time safety observation logging, two‑way communication, news‑reel updates and an SOS feature for lone workers.

Open APIs allow seamless integration with existing enterprise systems, while an admin portal supplies analytics on completion rates, onboarding times and error flags, enabling targeted interventions. Full deployment on construction sites has cut accidents by 62.63% per 10,000 full-time equivalents in two years and reduced onboarding to 15-25 minutes per user. User satisfaction averaged 4.56/5. Real-time dashboards give health and safety managers instant visibility of risk hotspots, supporting proactive mitigation and audit‑ready documentation.

Celebrate with the best

The winner will be revealed at the gala dinner at the London Marriott Grosvenor Square on 18 March. You can join the shortlisted entrants by booking your seats at the awards. There is an early bird discount for those who book tables by close of play 23 January.

The Digital Construction Awards are organised by Digital Construction Week, the Chartered Institute of Building, CM and Digital Construction Plus. Bluebeam, nima and Sage are among the sponsors.

To find out more about the awards, head to digitalconstructionawards.co.uk.

To become an awards sponsor, email Karolina Orecchini.