Six businesses have made the shortlist for Digital Consultancy of the Year at the Digital Construction Awards 2026.

This category rewards the digital construction consultancy that has demonstrated excellence and helped their client(s) transform their businesses or projects through the adoption of digital processes and technologies.

Here are the six consultancies that made the shortlist.

Drone Surveying

Drone Surveying addresses the challenges that housebuilders face in maintaining accurate earthworks and material management.

Traditional, manual surveys provide only a partial picture of onsite materials, making it difficult to manage the materials management plan (MMP) effectively. Inaccurate volume calculations lead to costly over- or underordering of aggregates, inefficient reuse of material, and compliance challenges with environmental regulations. These risks are exacerbated on large developments, which often comprise hundreds of plots.

Drone Surveying – as the name suggests – provides a digital, drone-based survey and consultancy service that uses photogrammetry and a secure online portal to capture, analyse and manage earthworks data.

Each drone flight collects high-density survey data across the whole site. This is processed into an accurate digital terrain model and orthomosaic imagery, then run through a volumetric analysis workflow to calculate the volume of every accessible stockpile. Drone Surveying’s in-house engineers enrich the dataset, naming and categorising each stockpile (eg topsoil, subsoil), tagging location and intended use, and aligning outputs with the client’s MMP. This provides a clear, auditable record of materials and supports planning and environmental compliance.

Visual reports and CAD files are generated and shared via an online portal, enabling site, commercial and technical teams to monitor progress, track earth movements and make decisions based on current, measured data rather than estimates.

Among Drone Surveying’s housebuilder clients, stockpile measurements are now accurate to within ±2%, compared with manual survey tolerances of up to ±15%. Survey turnaround has been reduced from several days to under 24 hours, giving near real-time visibility of earthworks progress and enabling faster approvals, valuations and change control.

Drone Surveying’s customers also report improved confidence in material quantities, delivering cost savings of up to 20% in aggregate management and haulage. Drone data collection also removes the need for operatives to climb or walk stockpiles, reducing exposure to slips, trips and vehicle movements. Clear records of surveys, volumes and stockpile histories provide robust evidence for CDM duties and planning conditions, supporting both safety governance and regulatory compliance.

Laminar Projects

Laminar Projects was brought in by a data centre developer to combat the challenges it faced in securing reliable progress updates. Fragmented, inconsistent data from every level of the supply chain meant management reporting was delayed, disconnected from site activity, and hard to trust. By the time issues surfaced, they were weeks old, too late for the project managers to act decisively.

Laminar’s project management, planning and controls, and data and digital teams worked in tandem to create end-to-end data environments that captured activity at the work front and turned it into unquestionable intelligence that everyone across the supply chain could understand and use.

The project management, planning and controls teams showed the client how data from the contractors was delayed, fragmented and inconsistent, which highlighted why issues were going unnoticed and why they couldn’t make fast, confident decisions.

The data and digital team rebuilt the data pipelines and governance structure with a stage-gated framework – define, design, develop, deploy:

- define – the real project information requirements were agreed with onsite teams;

- design – data capture was mapped directly from the source and connected to management reports (not retrofitted weeks later);

- develop – the pipelines and quality controls were built to ensure data accuracy and timeliness; and

- deploy – interactive Power BI reports with live links to site data were set up.

The result went beyond equipping the client with a better dashboard. Laminar triggered a fundamental shift in how their client plans, executes and governs their projects.

The data foundation gave the delivery team access to live information they could implicitly trust. Decision-makers no longer waited weeks for static performance reports or second-guessed progress data. They could interrogate the “why” behind schedule shifts as they happened.

Because the reporting was transparent and verifiable, trust between decision-makers and site teams grew quickly. Regional planning leads used data to challenge assumptions, identify blockers earlier, and communicate clearly with stakeholders. Leadership transitions no longer disrupted progress because structured reporting ensured continuity.

Planning became an enabler of rapid delivery, rather than a bottleneck. This allowed the client to maintain ambitious timelines while protecting quality and safety.

The developer is now using this data and planning framework across its European portfolio, proving its scalability and long-term impact.

Limes Consultancy

Limes Consultancy is a specialist in SME digital adoption and, through collaboration with Solving Construction, CITB, North London Loft Rooms and RLB Digital, developed an approach to help SME builders to successfully adopt digital tools and methods.

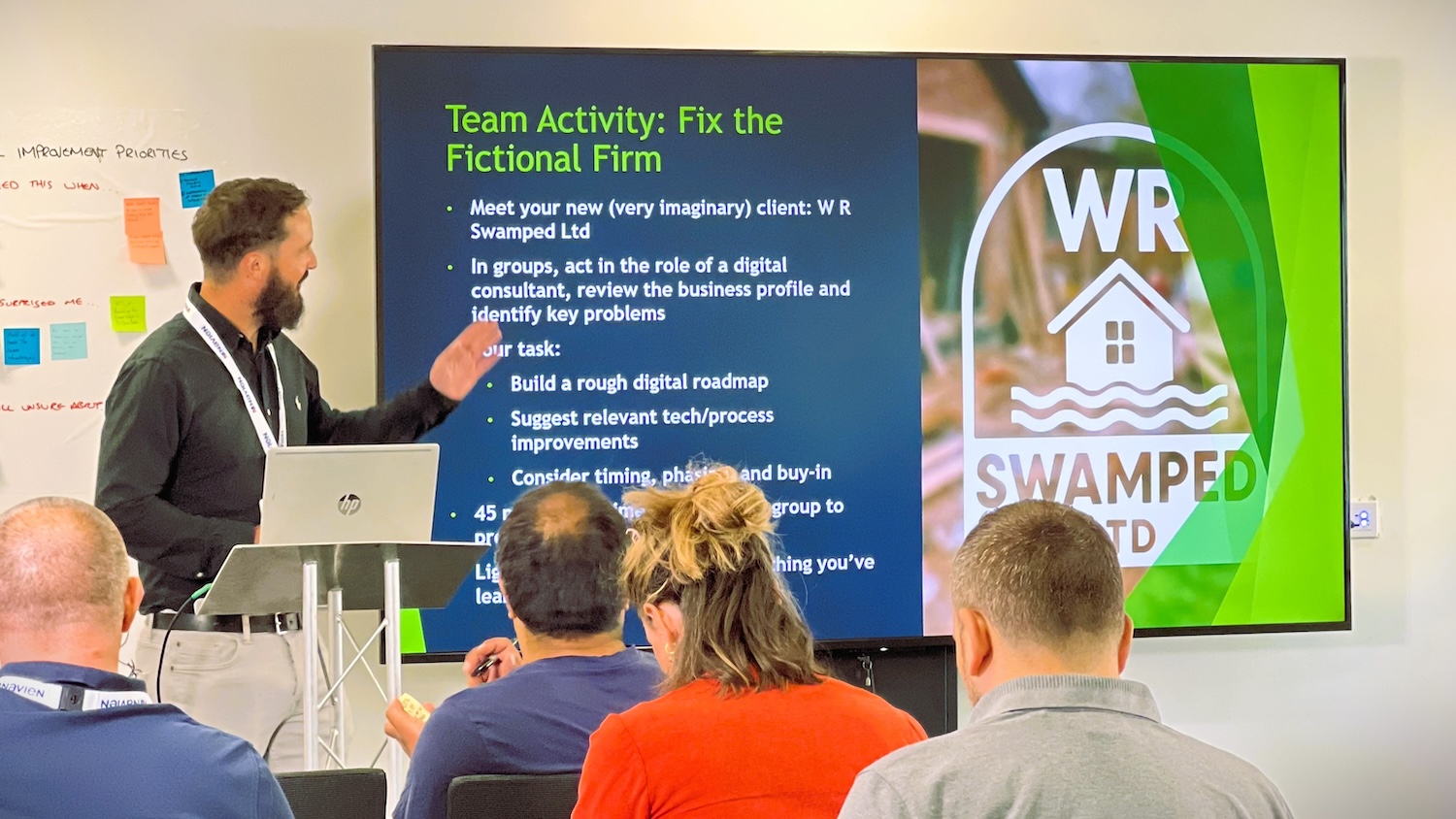

Limes led the content creation and delivery of the Solving Tech for Small Builders programme pilot aimed at 50 businesses. Rather than delivering confusing terminology, abstract digital training or a plethora of tools that may or may not be useful to attendees, the programme was built entirely around the real-world needs of SME builders.

Working with Solving Construction, CITB, North London Loft Rooms and RLB Digital, Limes designed a curriculum that balanced strategic awareness with hands-on application. The programme was structured around two elements: an in-person launch event that involved live discussions, a demonstration day and a wrap-up session; and a series of online modules that allowed attendees to build skills progressively, supported by curated vendor content, case studies and a series of workbooks.

Key to the approach was ensuring the technology was not demonstrated but contextualised. For example, rather than simply showcasing software, Limes walked participants through how it could resolve everyday pain points such as tendering, site capture, programme planning and cashflow management. Before even touching on technology, Limes walked businesses through key principles of time management, process mapping, change management and continuous improvement to ensure that tools wouldn’t just be purchased and forgotten, but would address real needs and then be introduced and ‘stick’ within their businesses.

The materials were designed to be digestible, avoiding jargon and ensuring content could be picked up and put down around busy project workloads.

For the participating SMEs, the programme delivered tangible, measurable benefits. Attendees’ confidence in adopting technology nearly doubled on a measured scale before and after the programme. Builders reported clearer workflows, improved collaboration and significant time savings. One company calculated that, by digitising its estimating and programme planning, it had reduced time spent on tendering by 15%. Another saw a huge reduction in overheads by simply rationalising its tech stack and using what it had available, saving the firm around £10,000 per annum.

Majenta Solutions

Majenta Solutions helped civil engineer George Leslie address issues it was having with stakeholder engagement. Leslie was already on a digital transformation journey, recognising that its technical experts were struggling to translate engineering concepts into formats accessible to diverse, digitally literate audiences, including local communities, regulatory bodies and clients, whose expectations have evolved beyond 2D planning documents.

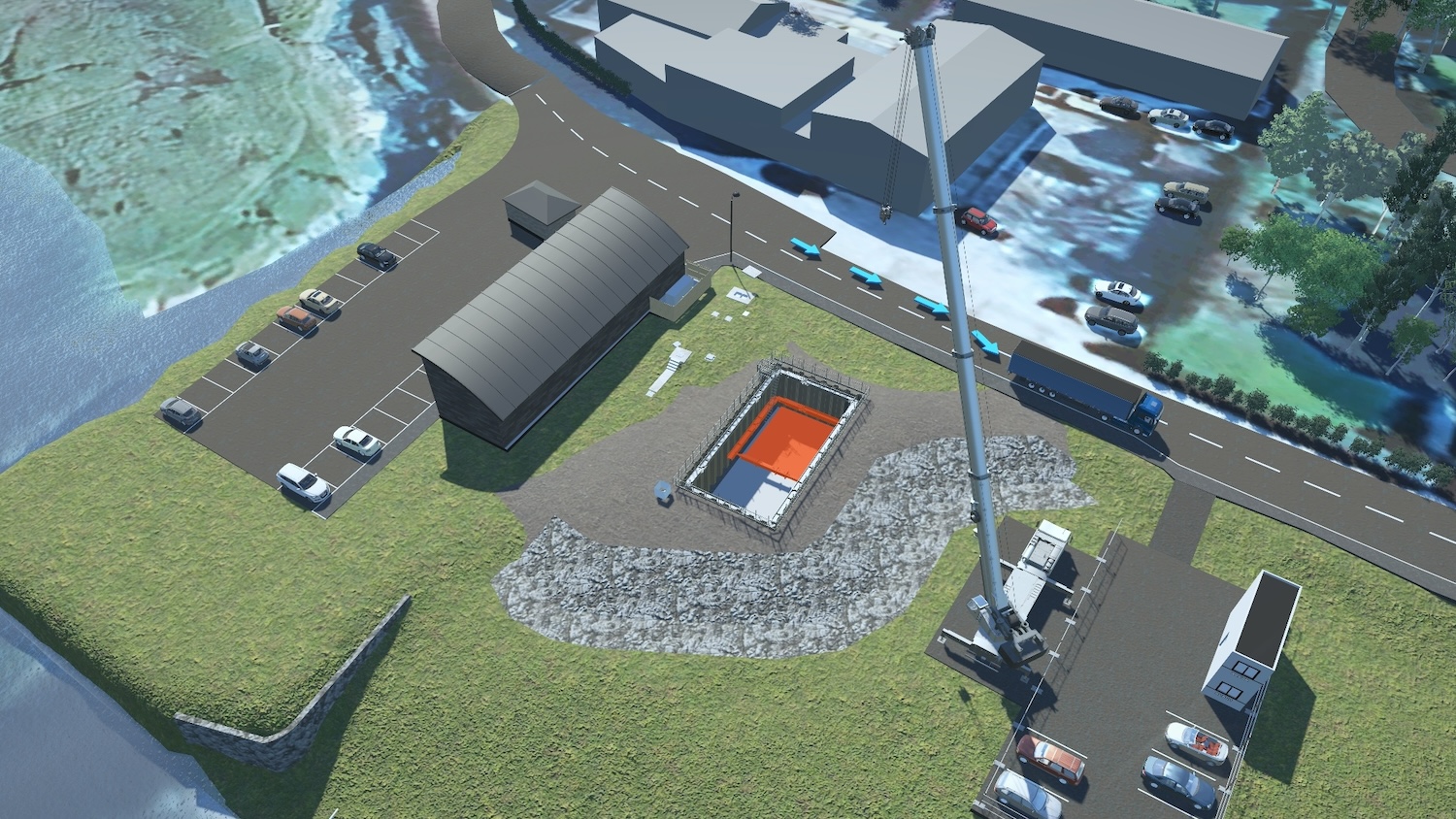

However, when its traditional, 2D approach wasn’t enough to ensure the Glencaple sewage network upgrade for Scottish Water secured planning permission, Leslie called in Majenta.

Leslie selected Majenta for its 3D and 4D modelling capability – the best solution to overcome the challenges threatening the Scottish Water project. Majenta’s solution could simultaneously serve multiple audiences: public consultations in town halls, remote governmental stakeholder presentations via Microsoft Teams, and internal construction planning. The model would provide a basis for consistent communication and joined-up thinking across all parties while maximising return on investment.

For the Glencaple project, Majenta developed detailed visualisations, integrating Mabey Hire’s 3D temporary works design model to ensure technical accuracy. Majenta worked collaboratively with Leslie to determine appropriate detail levels for different stakeholder groups. Public-facing models provided transparency without overwhelming complexity, while more detailed versions supported internal planning.

Specific viewpoint renders addressed community concerns identified by Leslie, including perspectives from residences and a local cafe. This bespoke approach demonstrated Majenta’s consultancy value: understanding the client’s stakeholder landscape and configuring technology to address actual challenges rather than delivering generic solutions.

The implementation process was deliberately designed for smooth adoption. Majenta supported its client in presenting the models at public consultations, building staff confidence. After Leslie expressed concern that showing comprehensive construction logistics might alarm residents unnecessarily, Majenta adapted by creating tiered visualisation levels.

The immediate Glencaple challenge was comprehensively resolved: the 3D and 4D visualisations enabled Leslie to support Scottish Water in securing planning permission. Leslie’s own estimates put the total time saved thanks to Majenta’s involvement at as much as three months, equating to roughly 15% of total pre-construction time and reducing costs by approximately £17,000.

Majenta’s consultancy extended beyond the Glencaple project. It provided CPD sessions for internal teams and supported Leslie’s broader digital implementation and strategy, helping the engineer to integrate 3D and 4D modelling as standard practice.

Teecom

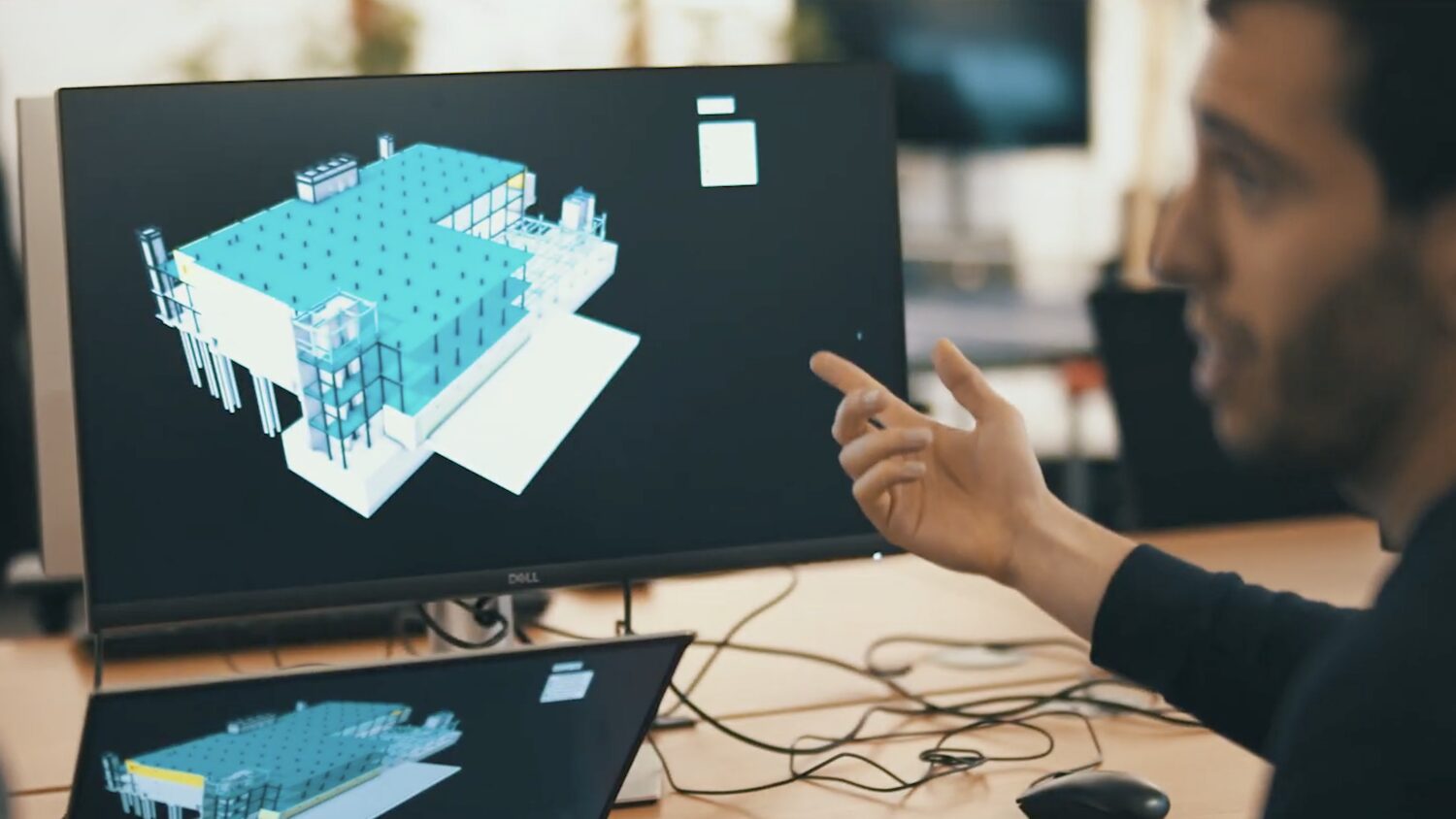

Teecom specialises in planning the technology within buildings. Through project experience across multiple sectors, it identified that recurring issues – such as manual device entry, inconsistent documentation and information silos – slowed progress and introduced risk. These pain points became the foundation for its digital strategy: applying software development principles, automation, version control and testing to building design.

This strategic shift resulted in the creation of Teecom’s internal suite of digital tools – ACS Arrangements, Rack Builder and Connectivity Schedules – and its Buildings as Code methodology. Each initiative was designed to remove friction from traditional workflows, improve collaboration between disciplines, and deliver measurable efficiency and accuracy gains.

ACS Arrangements automates the placement of access control devices across models, aligning with each client’s standards for mounting heights, device types and configurations. Rack Builder connects engineering data directly with Revit models, generating accurate layouts that stay automatically updated as specifications evolve. Connectivity Schedules synchronise information between drawings and schedules, ensuring every deliverable reflects the latest design intent.

Together, these tools reduce manual effort by up to 70%, eliminate duplication and ensure every output meets both client and industry standards.

For more complex systems, Teecom uses the Buildings as Code methodology. By capturing building and system requirements in a domain-specific programming language, Teecom can apply software engineering principles, such as version control, automated testing and type checking, to building design.

Programmatic rules, such as coverage requirements, device placement and system integration, are defined in code and automatically translated into constructible drawings. This approach not only improves efficiency, but also transforms quality: specifications become testable, traceable and extensible, reducing ambiguity and improving collaboration between disciplines.

Implementing these digital workflows required thoughtful change management. Teecom recognised early on that success depended as much on adoption as on technology. It invested in communication, training and documentation to ensure every team member had the resources and confidence to adapt. Each tool was launched through structured onboarding and supported by a shared knowledge base on GitHub. Leadership teams modelled adoption early, while internal digital champions provided hands-on support and shared best practices across teams.

WiiGroup

Rapidly growing electrical engineering specialist H&MV Engineering brought in WiiGroup to help it overcome its information management obstacles. Key functions such as commercial, planning, quality, safety and procurement operated largely in isolation, relying on spreadsheets and manual reporting. These disconnected processes created inconsistent data, duplication of effort, and a lack of real-time insight for both site teams and executives.

The challenge for WiiGroup was how to combine and deploy them effectively within a fast-scaling, multi-departmental organisation while reshaping workflows and embedding a digital-first culture. Resistance to change was anticipated, so WiiGroup adopted a co-design model – engaging users early through workshops and agile sprints, gathering feedback and iterating rapidly. This approach built confidence, reduced risk and ensured that each department saw its role in shaping the solution, turning potential resistance into engagement.

By designing around real workflows instead of imposing generic templates, the team ensured every solution was practical, relevant and immediately valuable. Early user involvement also supported consistent adoption: staff were not simply trained on new systems – they helped create them.

The result was the H&MV Performance Hub – a replicable, centralised data ecosystem built on Microsoft Fabric, integrating Power Platform tools to streamline data capture, reporting and insight generation. Information from multiple departments and regions now flows into a single, structured architecture. Role-specific Power BI dashboards provide real-time visibility into project performance, cost reporting, schedule health and delay analysis, while Power Apps and automated templates standardise data entry and eliminate manual reconciliation.

A standout feature is the Procurement Application, which first unified and standardised the procurement lifecycle across all UK projects, and was later rolled out to other regions across Europe. Security and governance were built in from the start, aligning with H&MV’s stringent IT policies and ensuring controlled access, compliance and transparency.

Data discrepancies have fallen by 80%. Reporting that once required days of manual consolidation is now completed instantly, cutting reporting effort by 35% – equivalent to roughly 3,600 staff hours saved every month. Live dashboards provide engineers, project directors and executives direct access to critical KPIs, increasing cross-departmental visibility by 70%, and allowing decision-makers to see the full project portfolio at a glance.

Celebrate with the best

The winner will be revealed at the gala dinner at the London Marriott Grosvenor Square on 18 March. You can join the shortlisted entrants by booking your seats at the awards. There is an early bird discount for those who book tables by close of play 23 January.

The Digital Construction Awards are organised by Digital Construction Week, the Chartered Institute of Building, CM and Digital Construction Plus. Bluebeam, nima and Sage are among the sponsors.

To find out more about the awards, head to digitalconstructionawards.co.uk.

To become an awards sponsor, email Karolina Orecchini.