Six methods for making the built and managed environments more sustainable have made the shortlist for Delivering Sustainability with Digital Innovation category at the Digital Construction Awards 2026.

This category recognises those organisations whose vision is an industry that places great importance on carbon efficiency: an industry that continuously measures and manages carbon through all project stages, basing project decisions on CO2e emissions, not just cost and time.

Here are the six entries that made the shortlist.

Emidat EPD Search Tool | Emidat

The Environmental Product Declaration (EPD) landscape is highly fragmented, scattered across multiple programme operators, each with different formats and search systems. As a result, procurers spend hours searching for verified EPDs and often discover too late that one does not exist, leading to product exclusion from tenders.

Data fragmentation and inconsistent file structures make it impossible to automate search and comparison without new technology capable of reading and structuring unstandardised content.

To overcome this, Emidat developed the EPD Search Tool.

Key components include:

1. Centralised search and discovery platform: EPDs from multiple programme operators are aggregated into one searchable database. Users can filter by product category, production country and verification programme.

2. User-friendly interface: each EPD features visual summaries of key environmental indicators, linked directly to the official pdf and product category rules (PCRs).

3. Rapid access and comparison: the platform supports both list and board views.

4. Standardised metadata and verification trust: EPDs are tagged with consistent metadata, including verification status, operator, country and product category.

5. Free scalable, low-barrier access.

6. Large language models (LLMs) process unstructured EPD pdfs and convert them into structured, searchable data.

Emidat plans to extend the tool with new features, including EPD comparability features and an API for downstream applications.

Halve the Half: the no- and low-cost opportunity to reduce cost and carbon | Cardiff Metropolitan University

Cardiff Metropolitan University’s estate ran on standard automated meter reading (AMR) data that showed a large amount of energy was being consumed when buildings were virtually empty. With mounting financial and net‑zero pressures, the university needed an immediate, low‑cost way to cut out‑of‑hours energy use without impacting comfort, teaching, research or residential life. Existing BMS controls were in place, but underused. On top of that, estate teams had been conditioned to avoid criticism, making organisational culture the biggest challenge.

The team adopted a ‘see‑act‑prove’ cycle using only the data and controls already available. AMR data was analysed in lightweight Excel models to rank buildings by total and out‑of‑hours consumption. Visualisations highlighted the worst performers. An energy manager then reset BMS schedules, fixed rogue timers, recalibrated setpoints, recommissioned drifted plant, cleaned filters and tightened domestic hot‑water regimes – all low‑ or no‑cost measures.

Changes were verified instantly against the same AMR feed, allowing rapid iteration and ensuring daytime comfort remained unchanged. The approach avoided any capital‑intensive upgrades, relying solely on existing meters, BMS and simple analytics.

During the academic year to 31 July 2025, gas use fell by 22.3%, electricity by 7.5% and water by 11.3% compared to the previous year. In absolute terms, the university saved 2.GWh of energy and approximately 10,000 cu m of water. Financially, the initiative resulted in around £700,000 in-year savings (adjusted for tariff reductions) and delivered immediate opex payback, freed budget for core missions and sparked a sector‑wide pilot across 12 UK universities to replicate the methodology.

Mynydd Isa Campus – delivering net-zero in operation school campus | Arup/IESVE

The Mynydd Isa Campus was commissioned to serve 1,300 pupils while achieving net-zero carbon in operation, a BREEAM ‘Excellent’ rating and 25‑year performance resilience to a +2°C future climate change scenario. Standard compliance modelling could not reliably predict long‑term energy use, unregulated loads, or the effectiveness of natural/dual‑mode ventilation needed to avoid mechanical cooling. Uncertainty around occupant behaviour and build quality variations (airtightness, commissioning) threatened the ambitious carbon and comfort targets.

Arup’s building physics team selected the software platform IESVE for its dynamic, physics‑based simulation capability. IESVE enabled parametric testing of glazing, airtightness, natural/ventilation strategies, heating/cooling loads and integration of a 1,080‑panel rooftop PV system.

The platform modelled unregulated energy uses, future climate files and occupant behaviour sensitivity in a single environment. Conservative build-quality scenarios were run, and close collaboration with the contractor refined onsite targets for airtightness and system commissioning. Results guided the dual‑mode ventilation design, heat recovery and electrical control strategy.

The campus opened last year as Flintshire’s first net-zero carbon in operation school and achieved a BREEAM ‘Excellent’ rating. The rooftop PV installation generates more than 500,000kWh annually, exporting surplus energy during summer and reducing annual CO2 emissions by more than 100 tonnes.

The building operates without mechanical cooling, maintains thermal comfort under future climate conditions, and provides Flintshire County Council with lower operating costs, verified performance and a low‑carbon learning environment.

Oxford Science Park | Tarmac/J Coffey Construction/Mace

The new 42,000 sq m Oxford Science Park development required air‑source heat pumps, renewable energy and advanced ventilation to meet its sustainability targets. Yet the specified high early-strength Portland cement concrete for reinforced slabs carried a large carbon footprint, threatening the project’s environmental goals.

Tarmac and J Coffey Construction teamed up to deploy Tarmac’s CEVO digital concrete platform, combining low‑carbon Portland limestone cement‑based mixes (30%‑50 % ground granulated blast furnace slag) with MixAI predictive optimisation and 53 embedded Converge maturity sensors.

MixAI forecasted strength and durability before placement, allowing selection of the lowest‑carbon mix that still met structural requirements. Real-time data transmitted from the onsite embedded concrete sensors enabled complete control of the building programme and material specification.

With this maturity data, the project team could validate performance and understand exactly what strength the concrete would achieve for the ambient temperature at the time. These insights gave Tarmac the opportunity to choose the most suitable mix with the lowest possible carbon value, without impacting strength or quality.

In total, more than 535 tonnes – or 38% – of CO2 was saved, compared with the original specification, resulting in a total carbon footprint of 869 tonnes of CO2 instead of the initially predicted 1,404 tonnes.

Vantage for University of Greenwich | iDEA

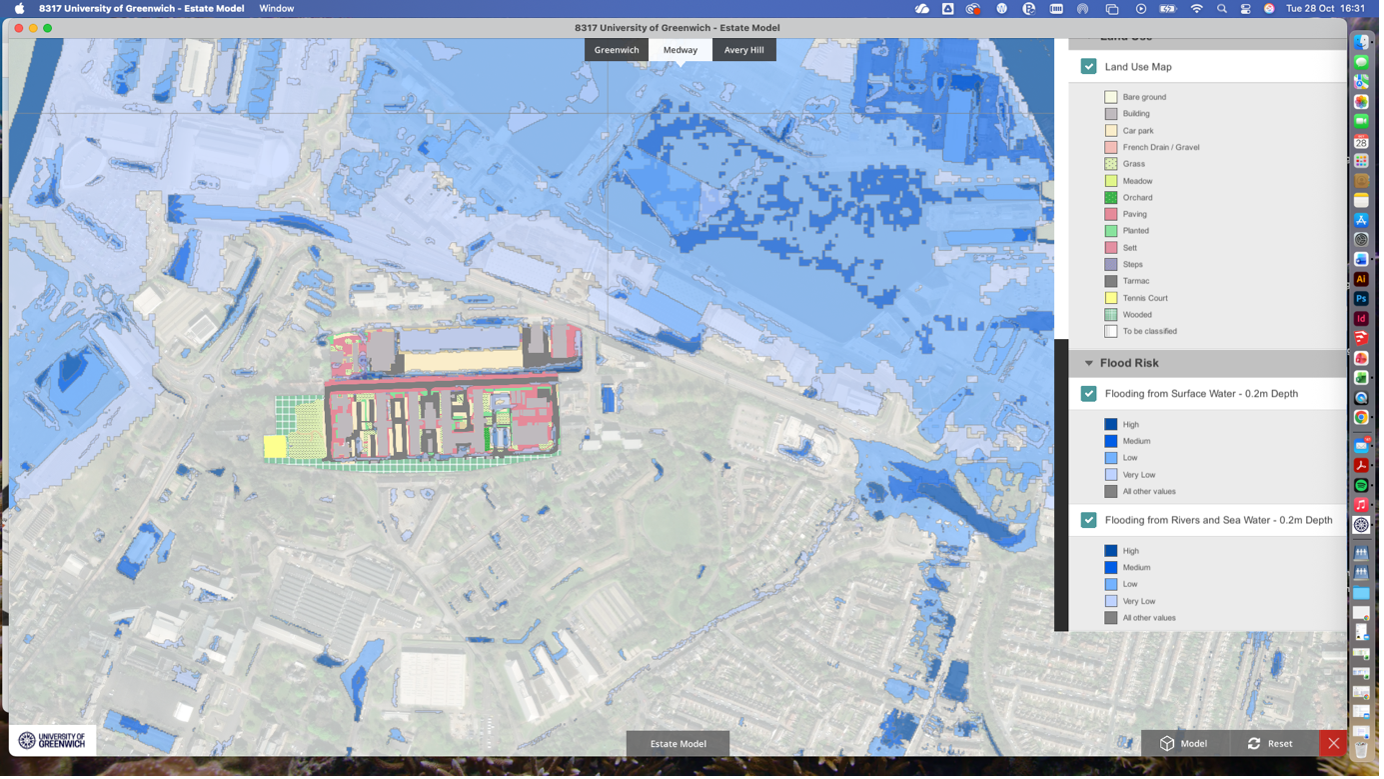

The University of Greenwich estate comprises 43 principal buildings across three campuses, totalling 115,000 sq m, ranging from nationally significant heritage and Grade I-listed World Heritage Sites to modern, purpose-built facilities. Ensuring a long-term property strategy for such a large estate requires accurate data.

iDEA was appointed by the university’s Estates & Facilities Directorate to clarify and consolidate existing data from spatial management information reporting (SMIR). Key challenges identified included: duplication, disparate and inconsistent sources utilising multiple systems, as well as limited access to critical information such as building condition and performance.

Addressing these issues, iDEA consolidated data into a unified, accessible platform – a single-source digital twin of the entire campus. Here, the SMIR could be reviewed, creating a baseline for future development and strategy.

The Vantage model visualises physical space across the campus using unlimited data layers. It incorporates space usage, building systems, building fabric, energy performance and climate risk. Data from existing systems, such as Micad, formed the initial footprint.

The Vantage environment allows users to search, filter and track metrics dynamically. It identifies priority projects, highlights inefficiencies, and informs strategic decision-making. Multiple datasets can be interrogated simultaneously to form thematic insights and guide scenario planning.

Adoption of Vantage has strengthened engagement and collaboration across departments. Regular dialogue and data sharing now provide transparency and insight into initiatives, allowing teams to identify opportunities and assess risks more holistically. Strategic plans are now developed in an integrated way that considers interdependencies across workstreams and long-term objectives.

WASTEie: a new language for smarter waste management | Morgan Sindall/BIMBox/University of Salford

The construction industry’s sustainability agenda has long prioritised energy and carbon performance, yet waste from construction activities is fragmented, and the data is poorly managed.

WASTEie, developed within the Reconmatic project, aimed to close this gap by creating a standardised digital framework for construction and demolition (C&D) waste information exchange. The goal was to make waste data interoperable, machine-readable and integrated into workflows.

Like COBie and FIREie, WASTEie provides a new language for 3D models to leverage waste data for intelligent decision-making. It delivered an open-standard solution for describing C&D waste, integrating buildingSMART methodologies. It also aligns with European Waste Classification codes for compatibility.

First, the team developed a clear structure for describing waste through both product and material properties. Reuse focused on compliance with regulations, and recycling on material properties.

A process map traced construction waste activities across the asset lifecycle, from early design through to demolition, which revealed opportunities to design out waste, capture accurate product data, and apply material properties and manufacturer take-back schemes that enable circularity.

Finally, the team compared existing data schemas and research to ensure alignment, using the buildingSMART data dictionary, linking it to IFC 4.3 and other relevant dictionaries such as Decommissioning and Reuse and RecycleBIM.

By aligning this work with IFC and Information Delivery Specification, the team enabled WASTie to automate date verification, ensuring that waste information is consistent, reliable and connected to specific project roles and lifecycle stages.

Celebrate with the best

The winner will be revealed at the gala dinner at the London Marriott Grosvenor Square on 18 March. You can join the shortlisted entrants by booking your seats at the awards.

The Digital Construction Awards are organised by Digital Construction Week, the Chartered Institute of Building, CM and Digital Construction Plus. Bluebeam, nima and Sage are among the sponsors.

To find out more about the awards, head to digitalconstructionawards.co.uk.

To become an awards sponsor, email Karolina Orecchini.